Albedometer – 3S-ALBEDO

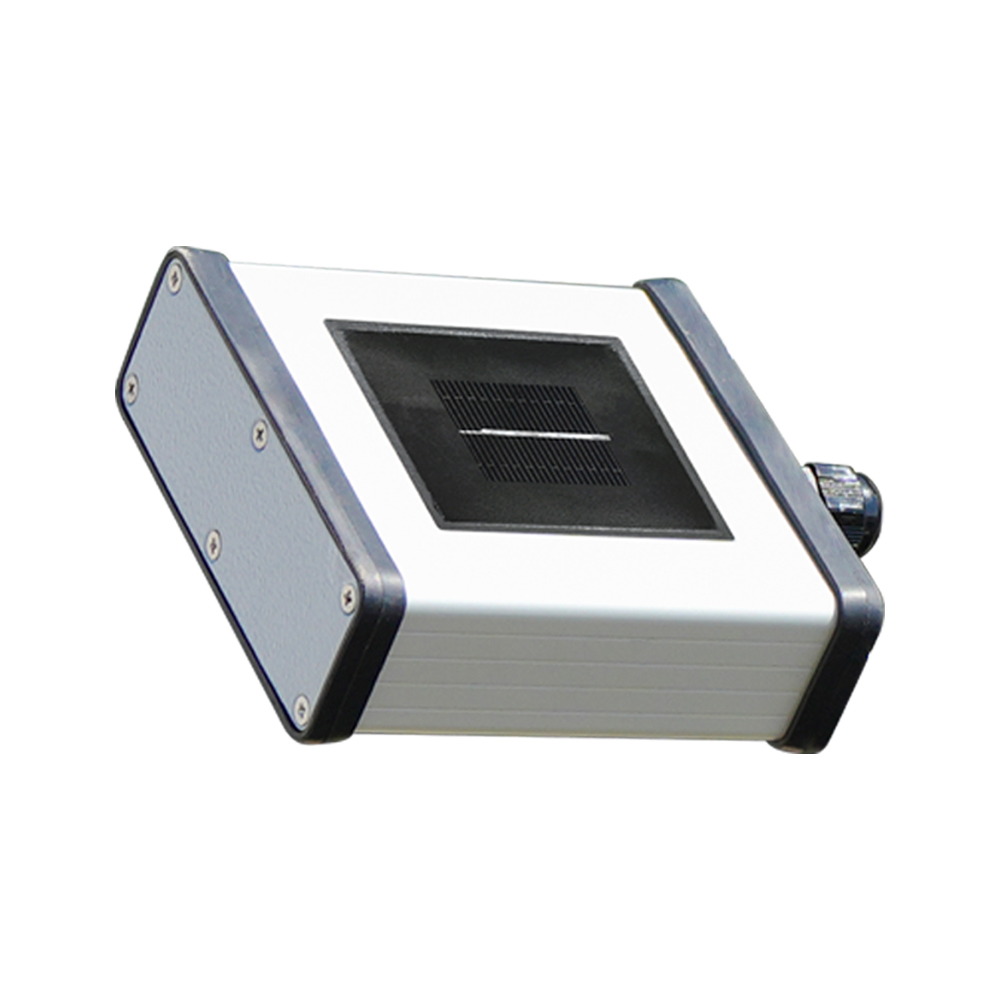

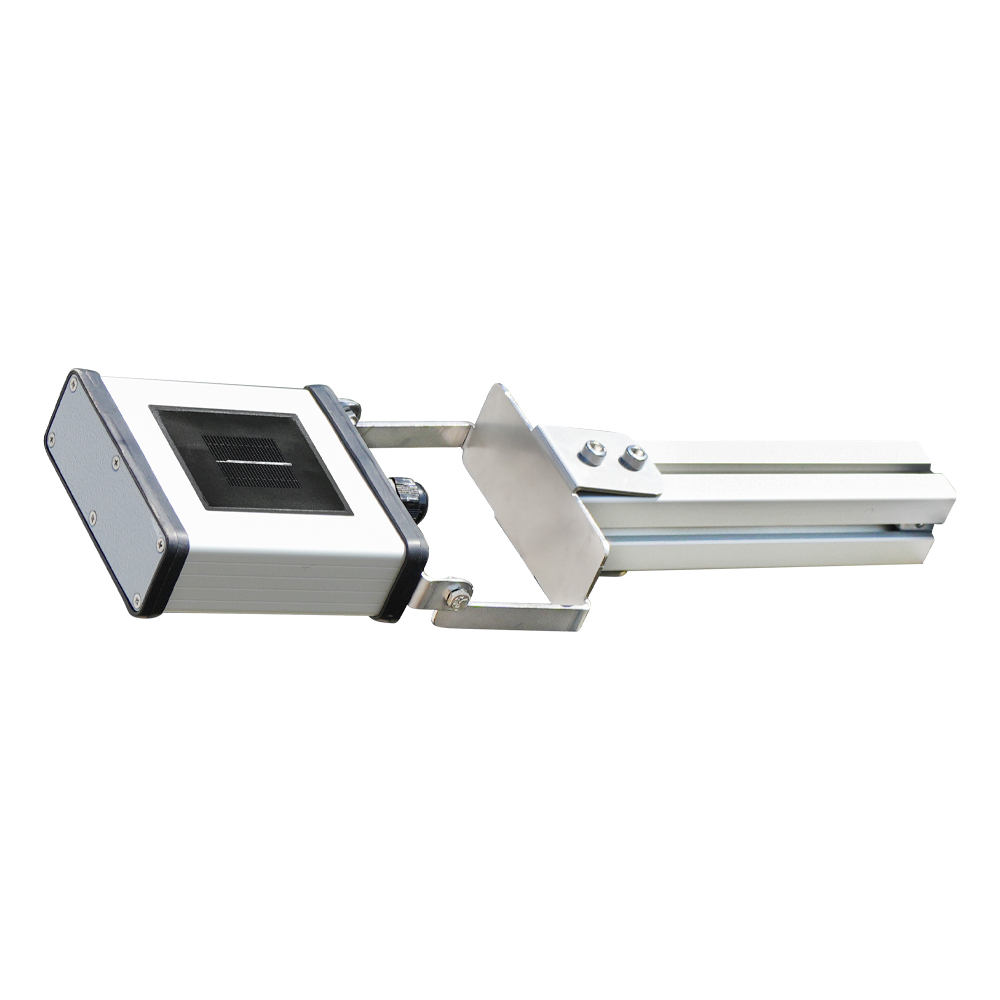

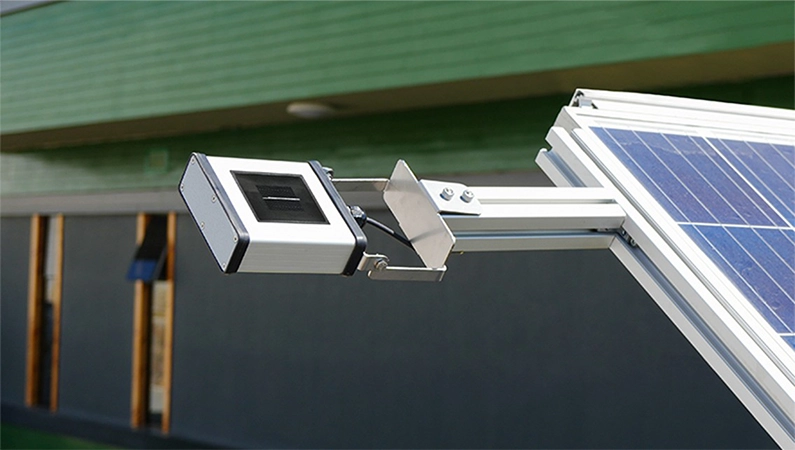

The PV Albedometer is designed to measure both irradiance values and the albedo ratio for bifacial solar panels. In addition to these key measurements, it also includes an internal cell temperature sensor. Each unit is supplied with a mounting bracket and cable for easy installation.

All measured meteorological data are transferred to dataloggers and receiver units via a 3-wire RS485 bus with Modbus RTU protocol.

TECHNICAL SPECIFICATIONS OF ALBEDOMETER

| Feature |

3S-ALBEDO |

3S-ALBEDO-2T |

| Sensor Type |

Silicone Reference Cell (31 x 31 mm) |

|

| Measured Data |

POA Irradiance, Reflected Irradiance, Solar Albedo, 2x Cell Temperature |

POA Irradiance, Reflected Irradiance, Solar Albedo, 2x Cell Temperature, 2 pcs PT1000 Module Temperature |

| Connectable Sensor |

– |

2x 3S-MT-PT1000 |

| Irradiance Range |

0 – 1600 W/m² |

|

| Albedo Range |

POA (greater than 0) GH (0-1) |

|

| Uncertainty |

≤1% (less than 2%; Class A as per IEC 61724-1 standard) |

|

| Resolution |

0.1 W/m² (less than 1 W/m²; Class A as per IEC 61724-1 standard) |

|

| Response Time |

1 sec. (less than 3 sec; Class A as per IEC 61724-1 standard) |

|

| Field of View |

170° (larger than 160°; Class A according to IEC 61724-1 standard) |

|

| Tilt-Azimuth Angle |

0°- 0° (less than 1°; Class A according to IEC 61724-1 standard) |

|

| Output Rate |

1/sec |

|

| Data Output |

RS485 up to 38400 Baud |

|

| Communication Protocol |

Modbus RTU |

|

| Power Supply |

12 … 30 V DC |

|

| Power Consumption |

20 mA maks @ 24 V DC |

22 mA maks @ 24 V DC |

| Cable Length and Description |

3 m 3x2x0.22 mm², 24 AWG LI2YC11Y-TP PUR Cable, UV and Weather Resistant |

|

| Galvanic Isolation |

1000 V between power supply and RS485 bus |

|

| Module Temperature Sensor Type |

Class A PT1000 according to EN 60751:2022 |

|

| Operating Temperature Range |

-40°C … +85°C |

|

| Box Dimensions |

138 mm x 112 mm x 39 mm (L x W x H) |

|

| Weight |

0.52 kg |

0.53 kg |

| IP Rating |

IP54 (Optional IP65, IP68) |

|

| Sensor Housing Material |

Aluminium |

|

| Standard |

IEC 61724-1:2021 and IEC 60904 |

|

| Calibration |

Each sensor is calibrated under Class AAA Sun Simulator as per IEC 60904-2 and IEC 60904-4 by using a reference cell calibrated by ISFH-Germany. |

|

| Origin |

TÜRKİYE |

|

What Does an Albedometer Do?

Solar irradiance is the amount of solar power received per unit area (W/m²). Monitoring irradiance is essential for evaluating the performance of PV plants. The 3S-ALBEDO sensor measures incident and reflected irradiance using a monocrystalline silicon solar cell, while also compensating for temperature effects thanks to its built-in PT1000 cell temperature sensor.

At its core, the albedometer consists of two reference cells in one box:

- The front cell measures the plane-of-array (POA) irradiance.

- The rear cell measures the reflected irradiance from the ground at the plane of array.

By comparing these values, the device calculates the solar albedo (the ratio of reflected irradiance to incident irradiance). This data is essential for evaluating the performance ratio of bifacial PV installations.

How Does the 3S-ALBEDO Sensor Work?

- A monocrystalline solar cell absorbs sunlight and generates current.

- A precision shunt resistor converts this current into measurable signals.

- The temperature sensor at the back of the cell corrects deviations caused by heat.

- An electronic card processes these signals and calculates compensated irradiance values in W/m².

- Data is sent to receiver units via RS485 using Modbus RTU.

Why Choose the 3S-ALBEDO Albedometer?

- Trusted accuracy: IEC 61724-1 Class A compliance with uncertainty ≤1%, calibrated as per IEC 60904-2 standards.

- Fast results: Response time of one second for real-time decision making. It can be reduced to 500 milliseconds upon request.

- Built to last: A UV-protected IP54 aluminum housing with optional IP65/IP68 ensures reliable operation in demanding outdoor environments.

- Quick setup: Plug-and-run design means fewer installation errors and faster commissioning. Supplied with mounting bracket and cable. Easy integration with any Modbus-compatible PLC, SCADA, or datalogger.

- Expandable: Supports connection of module temperature sensors for more accurate performance monitoring.

Available Models of the 3S-ALBEDO Albedometer

All models below are IEC 61724-1:2021 Class A compliant, factory-calibrated, and built with the same durable construction. The only difference is the number and type of external sensors that can be connected via RS485 Modbus RTU.

| Model | Communication | Uncertainty | External Sensor Options |

| 3S-ALBEDO | RS485 Modbus RTU | ≤1%, as per IEC61724-1 standard Class A | No external sensor can be connected |

| 3S-ALBEDO-2T | RS485 Modbus RTU | ≤1%, as per IEC61724-1 standard Class A | 2 x Module Temperature Sensors |

Frequently Asked Questions (FAQ)

1- Can this sensor connect directly to my SCADA system?

Yes, as long as your system supports RS485/Modbus RTU, the sensor will be fully compatible.

2- How are the sensors tested and calibrated?

Each irradiance sensor is calibrated under a Class AAA Sun Simulator as per IEC 60904-2 and IEC 60904-4, using a reference cell calibrated by ISFH-Germany.

The sensors are tested in natural sunlight against a reference cell calibrated by the Fraunhofer ISE Institute (Germany).

3- How often should I recalibrate the sensor?

Each unit is factory-calibrated and tested using reference cells calibrated by ISFH-Germany and Fraunhofer ISE. Recalibration every 2 years is recommended by IEC standards for maximum accuracy.

4- What is the price of albedometers?

Depending on the model and included accessories, the 3S-ALBEDO series is available between 930 and 1100 EUR.

5- Does the sensor include a cable?

Each unit comes with a 3 m 3x2x0.22 mm2, 24 AWG LI2YC11Y-TP PUR cable (UV and weather resistant) with 6 wires twisted (including ground for both Data & Power). Other lengths are available on request.

6- What are the delivery times?

- Small orders: approx. 2-3 weeks

- Bulk orders (100 pcs): approx. 8-10 weeks

7- How do I set up the sensor?

Follow our user manual which include step-by-step instructions for installing and configuring the sensors. We also provide remote setup support if needed.

8- What is the warranty?

All 3S-ALBEDO sensors come with a 2-year warranty.

9- What is the uncertainty of the albedometer?

The uncertainty is ≤1%, fully compliant with IEC 61724-1 Class A requirements (less than 2%).

10- Are the albedometers Class A?

Yes. Both SEVEN albedometer sensor models — 3S-ALBEDO, 3S-ALBEDO-2T— are Class A as per IEC standards.

11- Where can I calibrate the albedometer?

SEVEN Sensor provides calibration services at its facilities. Calibration is performed using a Class AAA Sun Simulator, in accordance with IEC 60904-2 and IEC 60904-4 standards, and referenced against a calibration cell certified by the ISFH Institute in Germany.

12- What external sensors can be connected to the albedometer?

The SEVEN albedometer can also function as a hub, supporting the connection of two module temperature sensors.