Automatic Soiling Sensor – 3S-SMS-MB

SEVEN Soiling Sensor is designed to measure the loss of energy production due to soiling caused by environmental factors on photovoltaic panels. The Soiling sensor, which is suitable for commercial, utility, industrial and rooftop projects, notifies the user of production losses due to soiling. If soiling ratio read from the sensor is 10%, it means that there is 10% energy loss in the facility.

TECHNICAL SPECIFICATIONS OF AUTOMATIC SOILING SENSOR

| Item Code | 3S-SMS-MB, 3S-SMS-GW, 3S-SMS-MB-24V, 3S-SMS-GW-24V |

| Soiling Ratio | 0% – 100% |

| Resolution | 0,1 |

| Uncertainty | ≤1% |

| Data Output | RS485 up to 38400 Baud |

| Communication Protocol | Modbus RTU |

| Output Rate | 1/s |

| Operating Temperature Range | -20°C … +85°C |

| Operating Humidity Range | 0 to 100% RH |

| Power Supply | 110-240V AC or 24V 5A DC |

| Power Consumption | 20 mA @ 24 V DC When the pump is passive |

| 3 A @ 24 V DC When the pump is active | |

| Electrical Connection | 3 m LI2Y(st)C11Y PUR Cable (UV and weather-resistant) |

| Galvanic Isolation | 1000 V between power supply and RS485 Bus |

| Water Tank Capacity | 18 Liters or 40 Liters |

| Water Consumption | 2 times filling per year |

| Washing Liquid | 100% Pure Water when the ambient temperature is above 0°C |

| 65% Pure Water + 35% Antifreeze when the ambient temperature is below 0°C | |

| Water Hose Length | 5 m (on request up to 20m) |

| Max. Water Line Height | 5 m |

| IP Rating | IP54 (Optional IP65) |

| Weight | 10.5 kg |

| Followed Standard | IEC61724-1 (Annex C) |

The system consumes approx. 100 mililiter water for single run for 2,5 meters water hose length. The water tank is able to serve 400 days (13.3 months). Consult SEVEN if the water hose longer than 2,5 meters.

Why Does Soiling Monitoring Matter for PV Plants?

Soiling, which is the accumulation of dust, dirt, and other particles on the surface of the PV panels, is considered one of the main factors affecting the PV panels’ performance. This accumulation has the ability to block the sun’s rays from reaching the solar cells, resulting in reduced energy production. Therefore, understanding the impact of dirt or dust on PV panels and using the appropriate equipment to address this issue can help improve energy efficiency and minimize maintenance costs.

Soiling is one of the silent performance killers in solar power. Depending on location, it can reduce annual energy yields by:

- 2–5% in moderate climates.

- 10–15% or more in deserts and industrial zones.

Without proper monitoring, plant operators either:

- Over-clean modules, wasting water and money.

- Under-clean, losing revenue from reduced output.

The SEVEN soiling sensor solves this by providing real-time visibility into performance losses, enabling data-driven decisions.

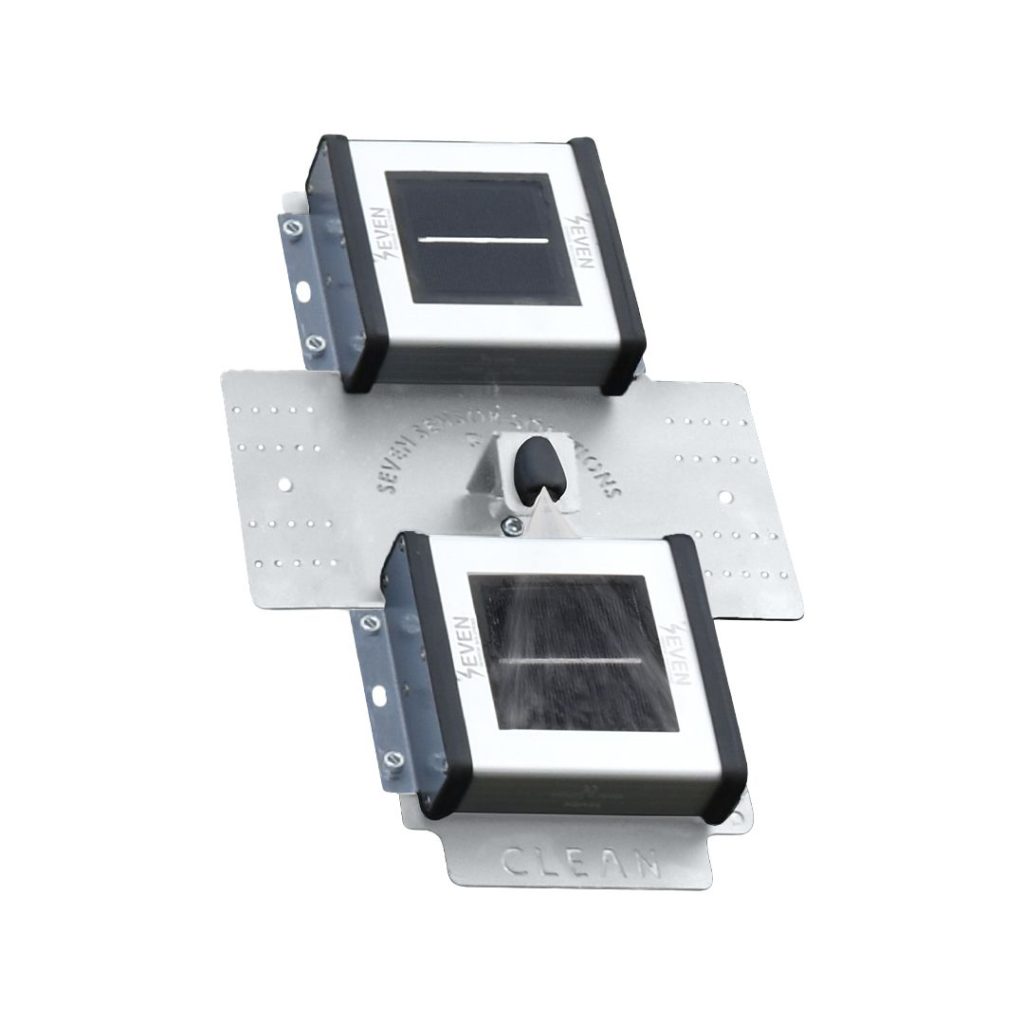

How Does the Automatic Soiling Sensor Work?

The working principle is straightforward yet highly effective:

- Two reference cells are installed side by side.

- One cell is automatically kept clean with a built-in washing system.

- The other cell is left exposed to dust and dirt, just like the PV modules.

- Irradiance values from both sensors are continuously compared using its specialized software.

- The difference is reported as a soiling ratio (%), showing exactly how much power the plant is losing.

- Data is transmitted via RS485/Modbus RTU to SCADA, PLC, or datalogger systems for easy integration.

This approach ensures that operators always see a true, up-to-date picture of losses caused by soiling.

What Benefits Does the Soiling Sensor Offer?

- Financial clarity – Know your exact production loss at any moment.

- Automatic cleaning system – Keeps one reference cell clean without manual work.

- Low maintenance – Uses only 36 liters of water per year (just two refills).

- Climate ready – Works in hot, humid, or cold regions (antifreeze option).

- Durable and reliable – Weather-protected housing (IP54 standard, IP65 optional).

- Seamless integration – Direct communication with Modbus RTU-based monitoring systems.

What are the Available Models of the 3S-SMS Automatic Soiling Sensor Sensor?

SEVEN offers four models of the Automatic Soiling Sensor, with or without a gateway.

- MB models connect directly to Modbus-compatible systems.

- GW models include a gateway that sends data to the SEVEN monitoring platform, allowing cloud-based access even without on-site SCADA/PLC.

| Model | Communication | Power Supply | Uncertainty | Gateway Option |

| 3S-SMS-MB | RS485 Modbus RTU | 100-240 V AC | ≤1%, as per IEC61724-1 standard Class A | Not Available |

| 3S-SMS-GW | RS485 Modbus RTU | 100-240 V AC | ≤1%, as per IEC61724-1 standard Class A | Available |

| 3S-SMS-MB-24V | RS485 Modbus RTU | 24 V DC, 5 A | ≤1%, as per IEC61724-1 standard Class A | Not Available |

| 3S-SMS-GW-24V | RS485 Modbus RTU | 24 V DC, 5 A | ≤1%, as per IEC61724-1 standard Class A | Available |

Frequently Asked Questions (FAQ)

1- Does the sensor comply with industry standards?

Yes. The 3S-SMS series fully complies with IEC 61724-1 (Annex C), the global guideline for PV soiling measurement.

2- How can I monitor the Automatic Soiling Sensor data?

The Modbus sensors are compatible with all dataloggers and SCADA/PLC systems with an RS485 input. Additionally, Seven Sensor offers a dedicated monitoring solution to address this need. The 3S-SMS-GW models include both a gateway and a yearly subscription to the SEVEN Monitoring System, enabling users to monitor, record, and store data continuously throughout the year.

3- Why does the system sometimes show the same soiling ratio as yesterday?

The soiling ratio is calculated as a daily average, based on stable data collected around solar noon. Results are updated after midnight. If insufficient stable data is collected (e.g. due to clouds), the system temporarily displays the last valid ratio.

4- What is “stable data”?

Stable data refers to irradiance values around solar noon when sunlight is strong and consistent. Low irradiance or rapidly changing weather conditions are excluded, ensuring only reliable measurements are used.

5- How often do I refill the water tank?

Under standard operation (one cleaning per day):

- The 18 L tank requires refilling about every six months.

- The 40 L tank requires refilling about once a year.

If cleaning frequency is increased, water use will rise and the tanks will need refilling more often. Always clean the tank before refilling to prevent algae buildup.

Our new model will be equipped only with a 40 L tank, which—due to its advanced nozzle design—will also require refilling approximately every six months.

6- Does the 3S-SMS-MB sensor record data?

Yes. The system can store up to one year of historical data, including:

- Daily soiling ratios

- Number of stable data points

- Water level status

- Sensor on/off records

Data can be viewed in the GUI or downloaded.

7- When does the cleaning take place?

By default, once per day for 5 seconds, about three hours before solar noon. Users can adjust cleaning times and increase frequency (up to 3/day) through the GUI.

8- Can I adjust the minimum stable data threshold?

Yes. It is set to 20 data by default, but you can modify it in the GUI.

9- Can the soiling sensor also be used as a standard irradiance sensor?

Not recommended. The Automatic Soiling Sensor includes two irradiance sensors:

- The clean sensor is calibrated like a standard irradiance sensor.

- The dirty sensor is normalized against the clean one.

Because of this normalization process, the dirty sensor cannot function as a standalone irradiance sensor. Even though the clean sensor gives accurate irradiance values, it requires daily automatic cleaning, which makes it unsuitable for long-term PR (Performance Ratio) calculations in the field.

10- Can I measure the soiling ratio using two regular irradiance sensors?

No. Simply comparing two irradiance sensors is not enough. SEVEN soiling sensors use a special IEC-compliant formula that considers factors such as:

- Latitude and longitude

- Date and time

- Sensor calibration and normalization

This process ensures far more accurate and reliable results than using two separate irradiance sensors.

11- How should I install and maintain the sensor?

- Install at the same tilt/orientation as the PV modules.

- Avoid placing near chimneys, vents, or reflective surfaces.

- During cleaning, ensure tracker-mounted sensors are angled downward to prevent water splashing onto the dirty sensor.

- Inspect cables, seals, and water tank regularly. Clean the tank at each refill.

- Perform a system check at least once a year (IEC recommendation).

12- Can the sensor operate in cold climates?

Yes. Use a 65% water + 35% antifreeze mix below 0°C to keep the system functional.

13- How can I connect the sensor to my system?

The sensor uses RS485 Modbus RTU communication, compatible with most data loggers and controllers. Follow our user manual which include step-by-step instructions. Contact SEVEN Sensor if further support is needed.

14- What are the delivery times?

- Small orders: approx. 2-3 weeks

- Bulk orders (100 pcs): approx. 8-10 weeks

15- What is the warranty period of 3S-SMS?

The sensor comes with a 2-year warranty covering defects in materials or workmanship.

16- What is the price of soiling sensors?

Depending on the model and included accessories, the 3S-SMS series is available between 1600 EUR and 2400 EUR.