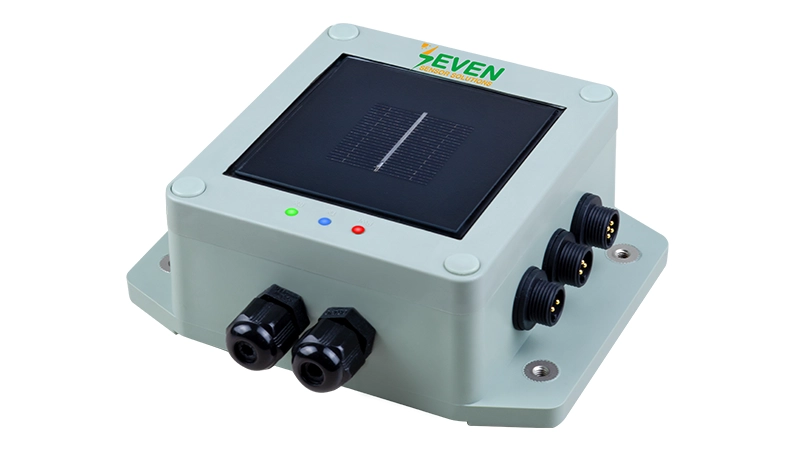

SEVEN will release soon an upgraded irradiance sensor designed to simplify field diagnostics with built-in LED indicators. This innovation’s purposes are mainly to reduce setup time, increase reliability, and offer visual feedback in real-time, making it easier for technicians to validate performance and connectivity instantly.

What Problem Does the New Sensor Solve?

Anyone who has spent time in the field setting up or maintaining solar monitoring systems knows the routine: you are often stuck troubleshooting a sensor with little to no visual feedback. SEVEN, a well-regarded name in high-precision meteorological sensors, is preparing to release a new version of its irradiance sensor that takes some of the guesswork out of the process.

What Is an Irradiance Sensor?

An irradiance sensor measures how much solar energy reaches a surface, expressed in watts per square meter (W/m²). These sensors are critical components in solar energy applications, especially for monitoring photovoltaic (PV) system performance.

SEVEN’s irradiance sensors are widely used from Japan to USA, and from Sweden to South Africa.

What’s New in This Irradiance Sensor Model?

The major innovation in this new model is the addition of three diagnostic LEDs located directly on the sensor housing. These indicators give technicians clear, immediate feedback in the field:

- Power LED

Illuminates when the sensor is receiving power and the input voltage is within the operational range (typically 12–24VDC). This makes it easy to verify power wiring at a glance. - Tx LED (Transmit)

Illuminates when the sensor transmits data over the Modbus RTU protocol. It helps confirm that communication from the sensor to the master device (such as a data logger or SCADA system) is working properly. - Rx LED (Receive)

Lights up when the sensor receives a valid Modbus command. This is especially useful when verifying if polling is active and if communication parameters like baud rate and slave ID are set correctly.

Why Are These Diagnostic LEDs Important?

Without onboard diagnostics, fieldwork often requires connecting a laptop and trying to connect the sensor to the configuration tool just to determine if it is working. This new design simplifies that process.

With the LED indicators, users can:

- Instantly verify that power is supplied to the sensor

- Confirm that data transmission and reception are functioning

- Reduce commissioning time significantly

This means that less time will be spent troubleshooting and more efficient deployment and support.

What Makes Integration Easy and Reliable?

Despite the internal upgrades, SEVEN has ensured that the sensor remains fully compatible with existing systems and installation hardware. Key features include:

- Modbus RTU over RS-485, fully compatible with third-party SCADA, PLCs, and well-known datalogger brands. It is also SunSpec compliant.

- <1.2% accuracy, making it Class A as per IEC61724-1:2021 standard.

- IP65-rated; suitable for outdoor use in all climates

- Wide operating temperature range, from -40°C to +85°C

In short, this sensor is ready for both new installations and upgrades in existing solar energy systems.

When Will It Be Available, and Who Should Use It?

The sensor is in final testing and should be available soon. It is made for:

- New solar sites where fast validation is key

- Retrofit jobs where better diagnostics save time

- Engineers and integrators who don’t want the hassle of constant field support

Whether you are working on a utility project, C&I PV plants, or a compact distributed system, this sensor is built to make your life easier.

Final Thoughts

SEVEN’s upcoming irradiance sensor combines the accuracy of its existing platform with a much-needed usability upgrade. The addition of Power, Tx, and Rx LEDs addresses one of the most common pain points in field diagnostics, making the sensor not just a measurement device, but a smarter tool for real-world conditions.

More information, including technical datasheets and ordering options, will be available at launch. Stay tuned for updates as SEVEN brings this sensor to market.

Frequently Asked Questions (FAQ)

Q: How does this model differ from the old one?

A: It has built-in LEDs that show power, transmit, and receive status — real-time feedback you can see right on the sensor.

Q: Can I use it with my existing system?

A: Yes, it’s fully compatible with standard mounting and Modbus-based systems.

Q: Is it rugged enough for outdoor use?

A: Absolutely. It’s IP65-rated and handles temps from -40°C to +85°C.

Q: What communication protocol does the sensor use?

A: It uses Modbus RTU over RS-485 and is SunSpec compliant.