As with all technological products, various malfunctions may occur in Seven Sensors during their usage due to environmental factors or product-related reasons. The detection, evaluation, necessary improvements, or product replacement processes are carried out within the scope of the product’s warranty period and conditions.

Our customers may contact our Technical Support Department regarding communication errors, data inconsistencies, mechanical faults, or similar issues with Seven Sensors. If our Technical Support Department is unable to resolve the issue through remote diagnostics, they request that the relevant product(s) be sent to our company for fault detection and further processing. Once the products arrive at our facility, they are received by the Technical Service Department through our Central Warehouse, and the Technical Service Process is initiated.

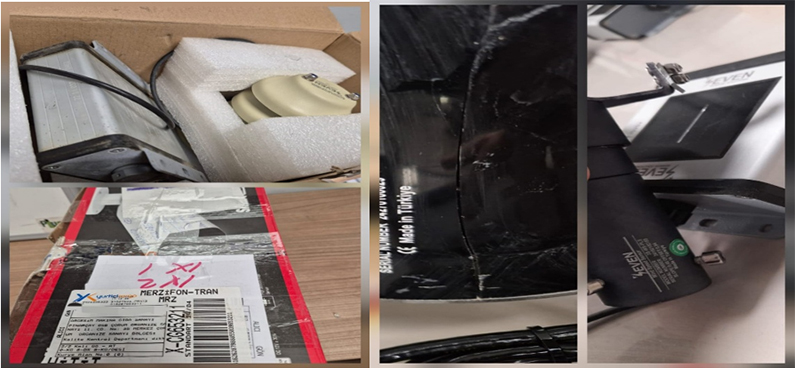

Before opening the package of the received products, a Technical Service File is created. The customer’s information and the reasons for returning the products are recorded in this file. The package is then photographed before being opened. After the package is opened, the products are visually inspected and individually photographed. Any mechanical faults detected during this visual inspection are recorded in detail in the Technical Service Report.

STEP 1: Communication Check

The products are connected via Modbus and power, and communication is tested. Our sensor configuration tools are used to attempt a connection with the devices.

Step 1.1: If Connection Is Successful

- The product’s initial calibration date, software version, and hardware version are identified.

- If the software or hardware version is not updatable, the product is evaluated under the warranty period, and a replacement process is initiated.

- If the versions are updatable, the product is delivered to the relevant technical unit for the necessary updates.

Step 1.2: If Connection Cannot Be Established

If the sensor cannot be connected or if the sensor parameters cannot be retrieved via the configuration tools:

- The sensor enclosure is opened.

- It is checked whether power and Modbus signals are received.

- It is verified whether the product draws excessive current.

- The physical condition of components on the electronic board is examined.

- Any detected faults are recorded in detail in the Technical Service Report.

- The product is then delivered to the relevant technical department.

- A general inspection is carried out, and necessary improvements are requested.

STEP 2: Return to Technical Service and Mechanical Inspection

After software or electronic updates and interventions are completed by the relevant technical department, the product is returned to the Technical Service Department for final inspections.

- Once the electronic issues are resolved, the mechanical structure of the product is thoroughly examined.

- Any mechanical faults (e.g., connector damages, cabling issues, deformation of external mechanical parts) are documented in the service report.

- The product is then sent back to the relevant department for a final mechanical inspection, and necessary improvements are requested.

Package Inspection and Mechanical Checks

STEP 3: Calibration and Final Evaluation Process

Products that have completed all technical procedures are once again delivered to the Technical Service Department for a general final check. Once electronic and mechanical issues are resolved, the product is sent for recalibration—specifically for Irradiance Sensors.

- The calibration process is carried out by the responsible unit.

- If calibration is successful, the product is handed over to the Technical Support Department for dispatch to the customer.

- If calibration fails, the irradiance sensor is deemed unusable, and replacement is initiated under warranty conditions.

STEP 4: Final Checks, Customer Notification, and Product Shipment

- After all procedures stated in the Technical Service Report are completed, final checks are carried out by the Technical Support Department.

- Sensor configuration tools and the Modbus Poll application are used to verify data and communication functionality.

- Once full functionality is confirmed, the customer is informed, and the return shipping address is requested.

- The product is carefully packed using its original packaging.

- A copy of the Technical Service Report is included in the package for customer reference.

- The product is handed over to the courier service for delivery to the specified address.

Notice

The Technical Service process must be handled carefully due to the sensitivity and usage conditions of the product. Malfunctions may not always be product-related; in some cases, user errors or external influences from the solar power plants where the products are installed—such as environmental conditions, system faults, or connection issues—may be the cause. It is recommended that customers notify our Technical Support Team of such issues in advance to ensure a smoother process. However, even if such information is not shared, external causes may still be detected during our electronic and mechanical inspections. Updates, repairs, or product replacements resulting from such user-related or environmental issues may not be covered under warranty, and service charges may apply for the related operations.