In the solar world, one thing is for sure, dirt happens. Whether it is dust in the desert or pollen in springtime, soiling on PV panels builds up faster than most people think. And when that layer of grime blocks the sun, your energy output starts to drop. That is why keeping track of panel cleanliness is just as important as monitoring performance.

SEVEN’s soiling sensor model, 3S-SMS-GW, is developed to do exactly that, and it does not stop there. This is not just any soiling sensor. It includes a gateway, which means it not only monitors soiling levels, but also sends real-time data straight to SEVEN Monitoring System which you can access to easily.

What Makes This Sensor Different?

At its core, the 3S-SMS-GW works in the same way as the Automatic Soiling Sensors: it compares the output of two PV reference cells, one cleaned automatically, and the other one exposed to dust in the same way as the installed panels. But what sets it apart is the combination of automatic cleaning and gateway connectivity, wrapped in a weatherproof design that is ready for the real world.

You do not have to manually clean the sensor. It takes care of that itself, using pressurized water to wash the clean cell daily. That means no more inconsistent readings just because someone forgot to wipe it down.

In addition, the sensor pushes data directly to SEVEN monitoring system using Modbus RTU (via RS485), so you always know how dirty your panels are, and how much energy that dirt might be costing you.

What else can you monitor through SEVEN Monitoring System?

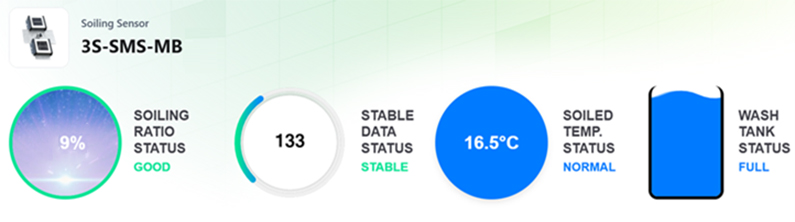

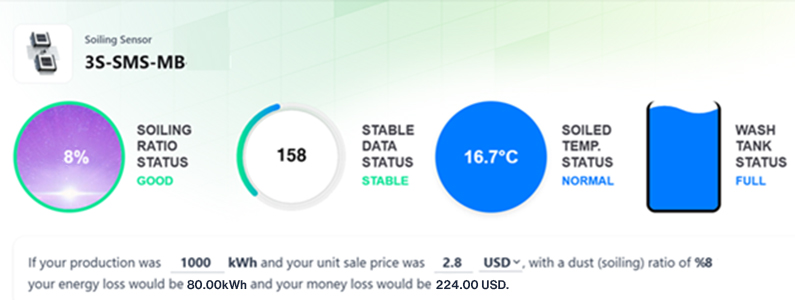

The SEVEN Monitoring System is designed to give users detailed insights. For the soiling sensor, it offers standard features such as:

- Daily average soiling ratio

- Stable data counter

- Water tank status (Full or Empty)

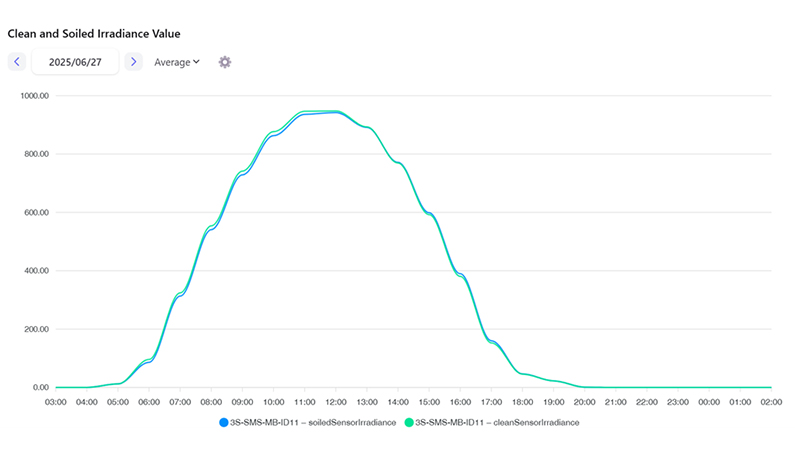

- Irradiance values (cleaned and soiled sensors)

Additionally, users can choose to monitor other parameters like:

- Instant soiling ratio

- Internal temperature of the device

The system is flexible; users can customize the graph type, set the time period, and generate graphs based on selected parameters.

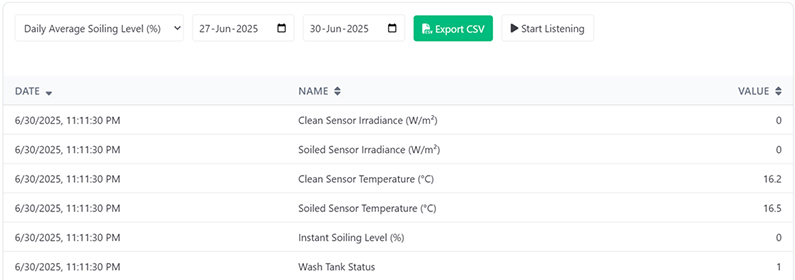

All data can also be viewed in a detailed table and exported as an Excel file by choosing the needed data and selecting the dates as shown below.

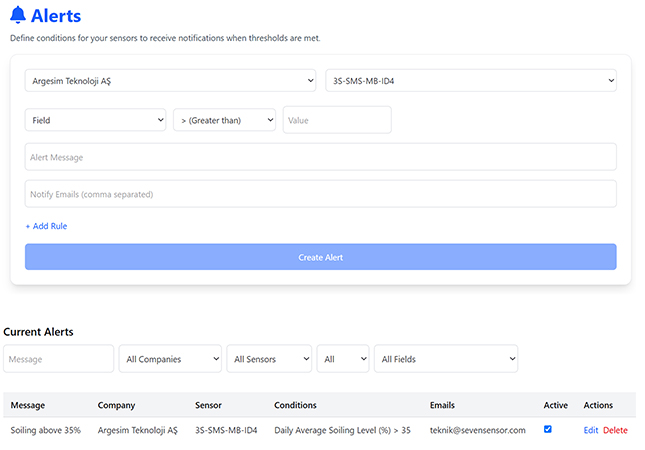

SEVEN Monitoring includes also alarm settings for soiling thresholds. For example, you can configure it to notify you by email when the soiling ratio exceeds 35%. This proactive alert system helps prevent performance drops due to delayed cleaning.

The SEVEN Monitoring System does not just monitor the soiling sensor. It supports integration with other sensors, offering a centralized and scalable solution for your PV plant monitoring needs.

Why You would Want This in your PV Plant

If you are managing a PV Plant in a place with wind, dust, or long dry seasons, this sensor could save you time and money. Here is why it stands out:

- No guesswork: You get clear data on when panels need cleaning, so you are not washing too early (wasting water and labor) or too late (losing energy).

- Hands-off operation: The cleaning is automatic, and with an 18-liter tank, it can run for 6 months without needing a refill.

- No extra boxes: Thanks to the built-in gateway, data flows directly into SEVEN monitoring system.

- Built for the elements:The sensor is rated IP65, so it can handle rain, heat, and dust without issue.

A Sensor That Pays for Itself

Nobody likes downtime or guessing when it comes to maintenance. With this sensor, you can plan cleanings based on real data, not assumptions. That means lower operational costs, better performance, and fewer surprises.

If you are serious about keeping your PV system efficient and low-maintenance, the 3S-SMS-GW is worth a look. It is already being used in hot, dusty climates where manual checks are tough and water is not always easy to come by.

For more details, including setup instructions and wiring, you can check out the user manual