Manual Soiling Sensor with Modbus Output – 3S-SMS-MB-M

The SEVEN Soiling Sensor is designed to accurately measure energy losses caused by dust, dirt, and other environmental factors on photovoltaic (PV) panels. By monitoring the soiling level, operators can directly see how much production is being lost. For example, if the sensor reports a 10% soiling level, it means the PV system is experiencing a 10% energy loss (PV Soiling = Energy Loss).

The measured soiling data is transmitted to data loggers and receiver units via a 3-wire RS485 bus using the Modbus RTU protocol.

TECHNICAL SPECIFICATIONS OF MANUAL SOILING SENSOR

| Item Code | 3S-SMS-MB-M |

| Soiling Ratio | 0% – 100% |

| Resolution | 0,1% |

| Uncertainty | ≤1% |

| Irradiance | 0…1600 W/m² |

| Followed Standard | IEC61724-1 (Annex C) |

| Data Output | RS485 up to 38400 Baud |

| Communication Protocol | Modbus RTU |

| Output Rate | 1/s |

| Operating Temperature Range | -40°C to +85°C |

| Operating Humidity Range | 0 to 100% |

| Power Supply | 12 to 30 V DC |

| Power Consumption | 20 mA @ 24 V DC |

| Electrical Connection | 3 m LIYYC11Y PUR Cable, UV and weather resistant |

| Galvanic Isolation | 1000 V between power supply and RS485 Bus |

| IP Rating | IP 65 |

| Dimensions | 244 mm x 108 mm x 42 mm (W x L x H) |

| Weight | 500 g |

| Calibration | Each sensor is calibrated under Class AAA Sun Similator as per IEC 60904-2 by using a reference cell calibrated by ISFH-Germany |

| Test | Each sensor is tested under natural sunlight by using a calibrated reference cell from Fraunhofer ISE, Germany.) |

Why Does Soiling Monitoring Matter for Solar Plants?

Even the most advanced PV modules lose efficiency when their surfaces are covered in dust or dirt. The impact varies depending on location and conditions:

- 2–5% annual loss in moderate climates (e.g., agricultural or suburban areas).

- 10–15% or more in desert, industrial, or high-dust regions.

Without dedicated monitoring:

- Over-cleaning wastes water, manpower, and maintenance budget.

- Under-cleaning reduces output and revenue.

By using the Manual Soiling Sensor, operators get real-time, quantitative data on actual energy loss. Instead of guessing, they can strike the right balance between cleaning costs and performance gains.

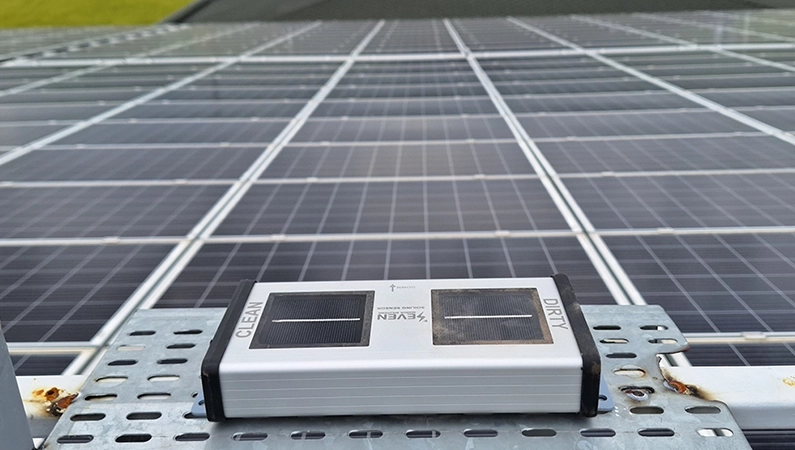

How Does the Manual Soiling Sensor Work?

The system is based on reference solar cells that mimic your PV modules.

- One reference surface is kept clean by manual intervention.

- The other is left exposed to the same dust and dirt conditions as the PV modules.

- By comparing the irradiance between the clean and dirty cells, the sensor calculates the soiling ratio in real-time.

This ratio is then transmitted via Modbus RTU protocol over RS485 to your data acquisition system. Because the device is SunSpec compliant, it integrates seamlessly into industry-standard monitoring platforms without extra configuration.

Key Benefits of the Manual Soiling Sensor

- Financial transparency – See exactly how much energy and revenue is being lost.

- Data-driven operations – Optimize cleaning schedules and avoid unnecessary costs.

- Flexibility – Suitable for utility-scale plants, commercial rooftops, and industrial projects.

- Durability – Weather-resistant IP65 housing, UV-protected cabling, and wide operating temperature range (-40°C to +85°C).

- Proven accuracy – Each sensor is calibrated under Class AAA Sun Simulator conditions with reference cells certified in Germany (ISFH and Fraunhofer ISE).

Frequently Asked Questions (FAQ)

1- How is the Manual Soiling Sensor different from the Automatic version?

The Manual version provides the same level of measurement accuracy but does not include an automatic cleaning system. Operators are responsible for manually keeping one reference cell clean. This makes it ideal for projects where cost efficiency is prioritized and regular site visits are already scheduled

2- Can I rely on it in extreme conditions?

Yes. With its IP65 rating and robust PUR cabling, the sensor is designed for challenging climates—whether desert heat, high humidity, or freezing conditions.

3- How is the sensor maintained?

Routine checks involve:

- Ensuring the clean reference cell is maintained free of dirt.

- Inspecting cables and connectors for damage.

- Verifying calibration annually for IEC-compliant accuracy.

4- Is it compatible with my monitoring system?

Yes. The device communicates using RS485 Modbus RTU and is SunSpec compliant, which makes it plug-and-play with most SCADA, PLC, or third-party monitoring platforms.

5- How often should I clean the reference surface?

The dirty cell in the Manual Soiling Sensor is exposed to fouling in the same way as the panels, while the clean cell must be manually cleaned daily by the user with a wet cloth. However, cleaning of the dirty cell should be carried out periodically together with site cleaning.

6- Does the sensor comply with industry standards?

Yes. The manual soiling sensor complies with IEC 61724-1 (Annex C) standard.

7- How is the manual soiling sensor calibrated?

The clean solar cell of the Manual Soiling Sensor is calibrated under a Class AAA Solar Simulator according to IEC 60904-2 and IEC 60904-4 standards using a reference cell calibrated by the Institute for Solar Energy Research (ISFH) in Germany. Calibrated solar cells are tested under natural sunlight using a reference cell calibrated by the Fraunhofer Institute for Solar Energy Systems ISE in Germany The dirty cell normalization process is performed on the clean cell after the calibration and testing processes are completed.

8- What are the delivery times?

- Small orders: approx. 2-3 weeks

- Bulk orders (100 pcs): approx. 8-10 weeks

9- What is the warranty period?

The sensor comes with a 2-year warranty against manufacturer defects.

10- What is the price of soiling sensors?

Depending on the model and included accessories, the manual soiling sensors are available at around 520 EUR – 950 EUR.