If you have worked on solar PV systems, you already know that weather sensors are nott optional. Whether you are watching for dips in solar irradiance, tracking ambient temperature swings, or monitoring wind gusts that could affect system stability, this environmental data plays a vital role in how your plant performs and how you manage it.

But just having sensors in the field is not enough. You also need a reliable and standardized way to get that data from the sensor into your SCADA system, logger, or cloud dashboard. That is where Modbus, and more specifically, SunSpec comes in.

Why Modbus? Why SunSpec?

Modbus has been around since the 1970s, and for good reason. It is simple, well-understood, and works across different kinds of networks, from RS-485 serial lines to modern TCP/IP setups. But here is the catch: the Modbus protocol itself doesn’t tell vendors how to organize their data. That part’s up to each manufacturer, and it is where things used to get messy.

The SunSpec Alliance stepped in to solve that. Rather than replacing Modbus, SunSpec created a consistent, open standard for how data should be laid out in Modbus registers. With SunSpec-compliant devices, you don’t have to reinvent the wheel every time you integrate a new sensor.

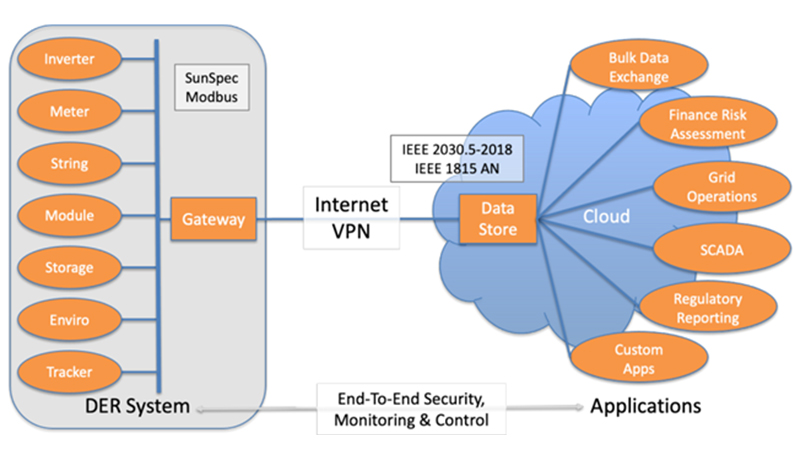

The SunSpec Alliance Interoperability Specifications are a set of documents that describe information models, data exchange formats, and communication protocols used in Distributed Energy Resource (DER) systems. The following diagram illustrates the components in a complete DER system:

What is a Modbus Register?

If you have ever flipped through a sensor’s documentation and found a huge list of numbered addresses with data types and descriptions, you have seen a Modbus register map. Think of registers like labeled bins where data gets stored. Each register typically holds one value: maybe the current temperature, maybe solar irradiance, or wind direction.

In SunSpec weather sensors, you will mainly encounter two types:

- Input Registers: These are read-only and store real-time sensor values like temperature or irradiance. Almost never used in standard SunSpec-compliant devices

- Holding Registers: They are the default and primary register type used by all standard SunSpec devices.

Standardized Models: Less Guesswork, More Consistency

SunSpec assigns model numbers to device types for plug-and-play compatibility. For environmental sensors, the SunSpec Modular Data Object approach is used:

- Model 701 – Sensor Base (DO Framework)

- Captures metadata (e.g., manufacturer, model, device type)

- Supports flexible DOs for:

- 703 – Irradiance

- 704 – Temperature

- 705 – Wind

- 707 – Status and diagnostics

- Each model starts with an identifier and length, allowing systems to walk through the register map without guessing.

- Once detected, each model’s structure is fixed and standardized, meaning no vendor-specific decoding is required.

What This Means in the Field

Let’s say you are installing a new site and using irradiance sensors from SEVEN, which are SunSpec-compliant. You plug the sensor into your system, and your logger immediately recognizes the register structure. So you don’t need to manually map data points or dig in the register maps. The data just shows up, accurately and consistently.

That plug-and-play compatibility is not just a time saver, it is a lifesaver when you are on a tight deployment schedule or trying to troubleshoot a system that is already live.

Whether you are commissioning a new PV plant or retrofitting an existing one, understanding how SunSpec uses Modbus registers is a must. It lets you integrate sensors faster, reduces room for error, and makes your system easier to maintain and expand.

In an industry where time is money and data drives decisions, predictable communication between devices is not just nice to have, it is essential. Do not forget: all SEVEN Sensors are SunSupec Compliant.