If you’ve ever worked with solar power systems, PV plants, or industrial sensors, you’ve likely come across terms like Modbus RTU and Modbus TCP. But what exactly do they mean, and more importantly, which one makes sense for your setup?

What is Modbus?

Modbus is a communication protocol that’s been used since 1979. It was designed to help industrial devices, like sensors, controllers, and data loggers, communicate reliably with one another.

There are a few good reasons why it has remained usable over time: it is open-source, easy to implement, highly reliable and widely supported by industrial hardware.

There are two main flavors of Modbus you’ll run into:

- Modbus RTU: used over serial connections like RS485 or RS232

- Modbus TCP: designed for Ethernet networks

What is Modbus RTU?

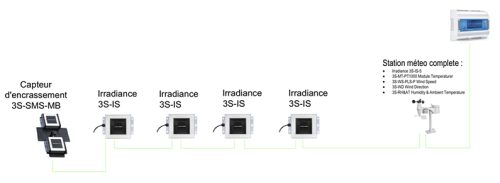

Modbus RTU is the most common version used in the solar PV industry. It typically operates via RS485, a robust and inexpensive form of serial communication that is ideal for long cable lengths and multiple devices, requiring only two wires.

One big reason for its dominance? is simplicity. Devices are connected in a daisy-chain layout: the master device (such as an inverter or datalogger) connects to the first device, which then connects to the next device, and so on. This setup is simple and reliable, especially in tough outdoor conditions such as those at solar farms.

Another major advantage is that: RS485 can handle distances of up to 1,200 metres without signal loss. This is a significant advantage when your sensors are spread out across a large PV field.

What is Modbus TCP?

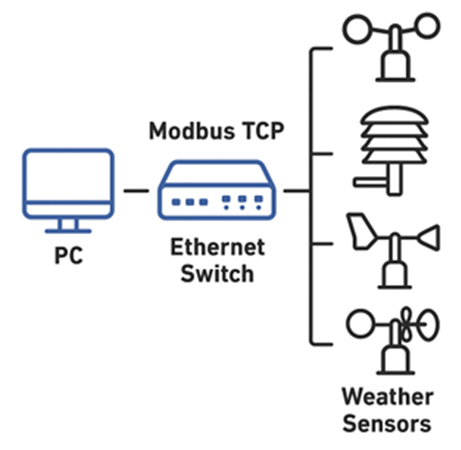

Modbus TCP Network Diagram for Solar PV Systems

Modbus TCP is built for Ethernet networks. It uses standard Ethernet cables. This version supports simultaneous communication with multiple devices, making it ideal for larger, more complex installations.

However, Modbus TCP does come with its own set of requirements. You will need Ethernet switches, cables and possibly routers. While Ethernet is fast and flexible, it is usually limited to around 100 m per cable length unless extenders or fiber optics are used, which adds cost and complexity.

Which one is better for solar applications: Modbus RTU or Modbus TCP?

In most utility-scale solar systems, Modbus RTU over RS485 is the preferred choice.

Why? Because it is cost-effective, robust and easy to deploy. No internet connection or networking equipment is required, and RS485 can manage long distances with minimal interference, even in challenging conditions such as dust, humidity, or electrical noise.

You’ll often find Modbus RTU used in all kinds of solar hardware: irradiance sensors, panel temperature probes, wind sensors, dataloggers, and inverters.

For this, Modbus TCP absolutely has its place too. It shines when you’re integrating with SCADA systems, doing remote monitoring, or working with smart grid-ready setups. In commercial or hybrid installations with advanced control systems, TCP may be the better fit.

Weather Monitoring in a Solar PV Plant

At Seven Sensor, we often provide sensors that can work with both Modbus RTU and Modbus TCP, thanks to a simple converter.

This gives you the flexibility to start with one setup and switch later if your system grows or your needs change. For example:

- In off-grid or remote PV systems, Modbus RTU over RS485 is usually the go-to. It’s low-power, simple, and doesn’t need much infrastructure.

- In grid-connected Systems, especially those using SCADA or cloud-based monitoring, using a converter to switch to Modbus TCP can give you faster data updates and easier integration.

Having both options means you won’t be locked into one type of communication. Whether you’re setting up a basic weather station or a comprehensive monitoring system, there is scope to expand and adapt.

Modbus RTU vs. Modbus TCP Comparison Table

| Feature | Modbus RTU | Modbus TCP |

| Communication Medium | Serial (RS485 or RS232) | Ethernet (RJ45 cables, switches) |

| Network Topology | Daisy-chain (multi-drop) | Star or switched Ethernet network |

| Typical Cable Length | Up to 1200 meters | Up to 100 meters (per segment, without extenders) |

| Speed | Slower (limited by baudrate) | Faster (10/100 Mbps and beyond) |

| Number of Devices | Up to 32 per bus (can be extended) | Practically unlimited (via IP addressing) |

| Installation Cost | Lower (simple wiring, no switches needed) | Higher (Ethernet gear required) |

| Interference Resistance | High (robust in harsh environments) | Moderate (requires shielding in noisy areas) |

| Ease of Integration | Easier in remote/off-grid setups | Easier with SCADA, smart grids, and IoT |

| Power Consumption | Very low | Moderate (due to Ethernet devices) |

| Use in Solar PV | Ideal for sensors, inverters, combiner boxes | Ideal for SCADA, remote/cloud monitoring |

| Data Transmission | One device at a time (master-slave) | Multiple devices can communicate simultaneously |

| Typical Use Case | Small to medium systems, remote areas | Commercial-scale systems, smart integration |