Module Temperature Sensor-PT1000 with 0-10V Output – 3S-MT-PT1000-U

Module temperature sensor measures the back of the solar panels temperature in degrees Celsius (°C) by using a PT1000 probe. The probe, used to measure the Back of Module Temperature, is placed between two Backsheet with EVA sheet. In order to communicate via 0-10V, a transducer is used to convert PT000 to the required Output signal. This Module Temperature Sensor Model is compatible with all Dataloggers, Gateways, and PLCs with 0-10V input port.

What is Module Temperature Sensor?

In solar power facilities, the overall field performance is greatly impacted by module temperature. The backside temperature of solar panels is measured in degrees Celsius (°C) using a PT1000 probe.

Because photovoltaic panels produce heat in addition to energy when exposed to sunlight, this measurement is crucial. The PV cells’ temperature rises as a result of some of the radiation being transformed into electrical energy and the remainder being dissipated as heat. The electrical efficiency of the module is reduced as cell temperature rises because the short-circuit current rises and the open-circuit voltage falls. Therefore, monitoring panel temperature is crucial to monitoring and managing these efficiency losses.

What is the working principle of Module Temperature?

Professional, intelligent measurement sensors with a digital interface, module temperature sensors are used in industrial and environmental settings, including photovoltaic power plants. The device is a temperature transmitter made especially to track the back surface temperature of photovoltaic modules. It has an analog 0–10 V output. A high-precision PT1000 sensor measures the PV module’s temperature, and an electronic card housed in a UV-resistant, highly protective enclosure converts it to an analog 0–10 V output. All dataloggers, gateways, and PLCs having 0–10V input ports can use this module temperature sensor model.

Technical Specifications of Module Temperature

| Item Code | 3S-MT-PT1000-U |

| Sensor Type | PT1000 |

| Measuring Range | -40°C to +85°C |

| Accuracy | ±0.1°C |

| Resolution | 0.1°C |

| Data Output | Analog 0-10 V |

| Power Supply | 12 to 30 V DC |

| Power Consumption | 15 mA @24 V DC |

| Electrical Connection | 1 m 2x2x0,22 mm², 24 AWG, LI2YC11Y-TP PUR Cable, UV and Weather Resistant |

| Operating Temperature Range | -40°C to +85°C |

| Box Dimensions | 65 mm x 115 mm x 55 mm (W x L x H) |

| Sensor Cover Dimensions | Ø 33 mm x 3,5 mm Plastic model Ø 35 mm x 2 mm EVA model |

| Weight | 267 gr |

| IP Rating | IP67 |

| Box Material | ABS |

| Sensor Cover | Laminated Backsheet (EVA – Tedlar) / ABS Plastic Injection |

| Mounting Method | 3MR Tape to Back of Module |

| Standard | Class A according to IEC 60751:2022 and IEC 61724-1:2021 |

How should Module Temperature be installed?

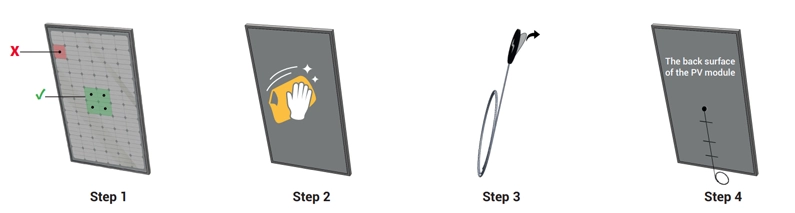

IEC 61724-1:2021 stated that “the module temperature sensor shall be placed at the center of a cell near the midpoint of the module, avoiding cell boundaries.”

This implies that the Module Temperature Sensor needs to be placed precisely in the middle of the PV module’s back. To keep the sensor from going beyond cell boundaries, it should be placed closest to the center of the cell. For precise measurement and a safe connection, the installation area must also be totally dry and free of contaminants. It should be mentioned that in the winter, dew residues on the PV modules may make it difficult for the Module Temperature Sensor to attach.

What are the advantages of Module Temperature?

Because they maximize performance, avoid overheating, and allow for weather adaption, module temperature sensors are essential to photovoltaic (PV) systems. Their significance can be explained as follows:

Estimating PR: To determine the Performance Ratio (PR) precisely, the module temperature must be measured. Since temperature directly affects electrical output and precise temperature data is required for precise PR calculations, a module temperature sensor is required.

Protection Against Overheating: PV panels can suffer long-term damage and performance degradation from excessive heat. Sensors that offer real-time temperature data allow control systems to start cooling techniques or change panel tilt to prevent overheating. This prolongs service life, lowers maintenance costs, and enhances sustainability in addition to protecting the system.

Weather Adaptability: The constantly shifting weather conditions that PV modules function in are further impacted by climatic variability. The system may react dynamically thanks to temperature sensors, which maximize energy yield by maximizing performance in a variety of weather and season circumstances.

Why Seven Sensor Solutions?

In order to provide accurate meteorological data for industrial and environmental applications, SEVEN products are constructed with dependable, premium components. The structure of the module temperature sensor, which closely resembles the backside structure of a PV module, is one of its main advantages. This guarantees that the heat transfer behavior of the sensor and the PV module is comparable, which is a necessary condition for precise measurement.

The sensor is designed to precisely satisfy the needs of photovoltaic plant monitoring systems, adhering to Annex B of IEC 61724-1:2021 and IEC 60751:2022. For instance, IEC 61724-1:2021, Section 9.1 states that cabling should be routed across cells whenever feasible and that rear-side temperature sensors and wiring for bifacial modules cannot cover more than 10% of any cell area. Furthermore, temperature sensors need to have an uncertainty of ±1 °C or less and a measurement resolution of < 0.1 °C.

The SEVEN 3S-MT module temperature sensor fully satisfies these requirements. Our module temperature sensor delivers a resolution of ≤ 0.1 °C with an uncertainty of ±1 °C, fully aligning with the IEC standards.

Frequently Asked Questions (FAQ)

1- What is the Class?

All 3S-MT-PT1000-U sensors are Class A according to IEC 60751:2022 and IEC 61724-1:2021.

2- What is the warranty?

All 3S-MT-PT1000-U sensors come with a 2-year warranty.

3- What is the price of module temperature sensor?

The price of module temperature sensor with 0-10V output is between 90 and 160 EUR.

4- What are the delivery times?

Small Orders: approx. 2-3 weeks

Bulk orders: approx. 7-8 weeks

5- Does the sensor include a cable?

Each unit comes with a 3 m 2x2x0,22 mm², 24 AWG, LI2YC11Y-TP PUR cable (UV and Weather Resistant). Other lengths are available on request.

6- How do I set up the sensor?

Follow our user manual which include step-by-step instructions. The user manual link is https://www.sevensensor.com/files/d/en/Module_Temperature_Sensor_User_Manual.pdf