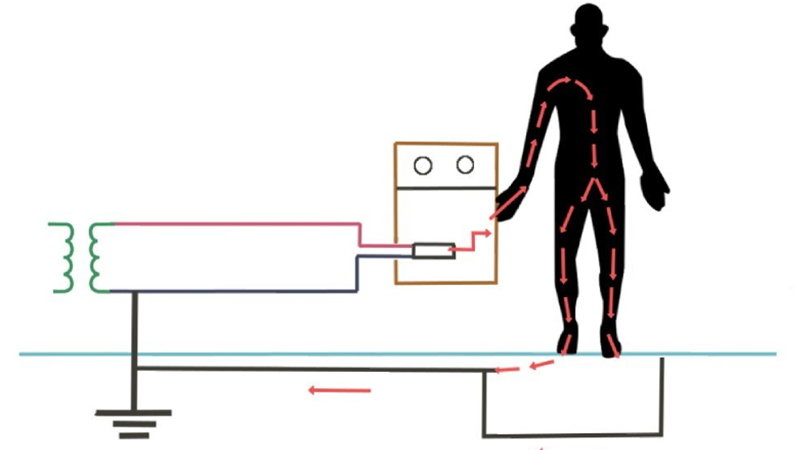

Grounding is a vital safety measure taken in any environment where electricity is present, to prevent the danger of electrical leakage.

It is a simple yet crucial system in which stray electrical current is transferred to the earth through a conductor.

Why is Grounding Important?

Grounding must be implemented wherever electricity exists in order to first protect human life and health, and secondly to avoid risking the lifespan of electrical devices.

This is the basic definition of grounding.

The metal parts of all electrical machines, metallic sections of pipes, lead sheaths of lead-covered cables, panels, and steel constructions or similar components must be grounded.

How Many Types of Grounding Are There?

Grounding is categorized into three main types:

- Protective Grounding

- Operational (System) Grounding

- Functional Grounding

Electrical Panel Grounding

Protective Grounding

Protective grounding refers to the grounding of conductive parts that are not normally live (not under voltage), in order to protect against potential electric leakage in the event of a fault.

The primary purpose is to ensure the safety of both people and electrical equipment.

Where is Protective Grounding Applied?

- Power Transmission Poles

- Electrical Panels

- Transformers

- Electric Motors

- Surge Arresters (Lightning Arresters)

- Circuit Breakers and Disconnectors

- Armored Cables

- Household Electrical Devices

Protective Grounding

Operational Grounding

Operational grounding refers to the grounding of a point in the circuit or panel where the operating current flows, in order to allow solar power plants and electrical devices to function within their normal standards.

This type of grounding is implemented in accordance with national regulations.

According to local regulations in our country:

- Medium voltage networks are grounded through a resistor,

- High voltage networks are grounded directly.

Unlike protective grounding, the primary purpose of operational grounding is not personal safety, but rather to ensure efficient system operation, protection of equipment, and safe system management.

Locations Where Functional Earthing Is Implemented

- Star points of generator stator windings

- Star points on the LV (Low Voltage) side of distribution transformers

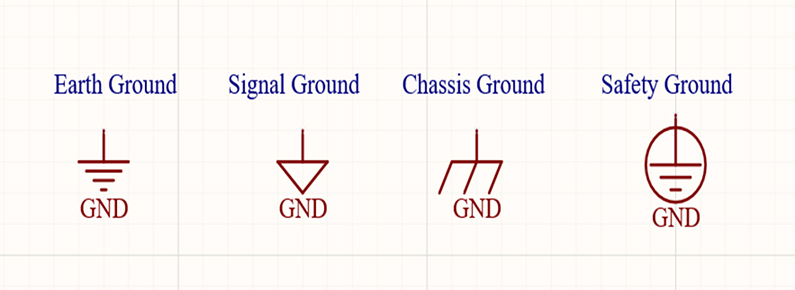

Electronics ground symbols as defined in IEC 60417

Locations Where Operational Grounding is Applied

- Star (neutral) points of generator stator windings

- Star (neutral) points on the low-voltage (LV) side of distribution transformers

Applications of Functional Grounding

- Computer systems

- Low-current (signal-level) devices

- Telecommunication facilities

- Railway systems

- Base stations

- Protection against lightning effects

- Radar and radio communication systems

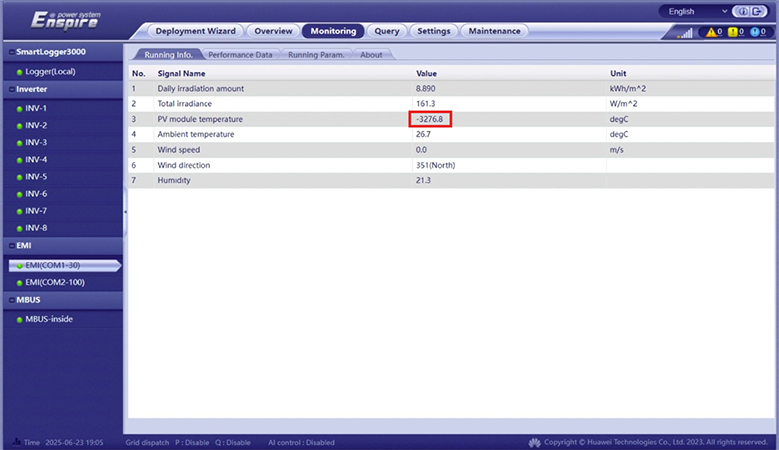

What Issues Might You Encounter with Seven Sensor if Your Grounding is Not Proper?

You may experience occasional errors in Modbus communication.

Specifically, abnormal values such as “-”, “0.0”, “-32768”, or “65535” can appear in data coming from temperature sensors.

These kinds of issues usually indicate communication problems caused by external disturbances, often related to inadequate or faulty grounding.

Erroneous Temperature Readings in Monitoring Systems Due to Grounding and Magnetic Field Interference

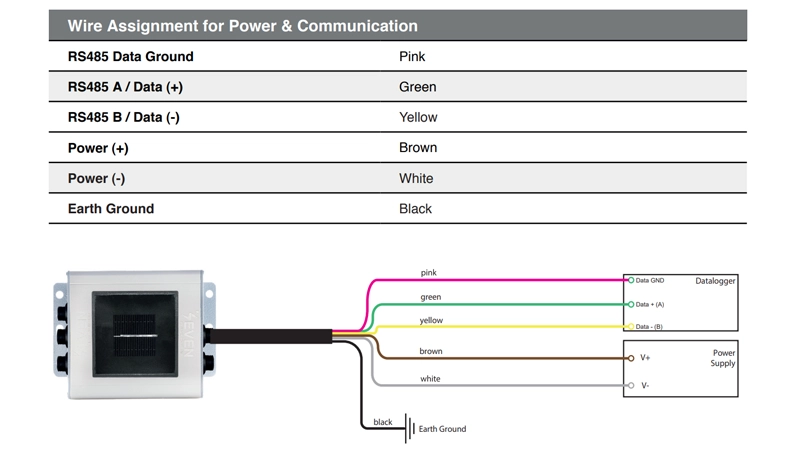

As SEVEN Sensor, we have developed various measures to minimize such issues. We have added grounding lines to the communication cables of our sensors for both Modbus communication and power connections. Additionally, to prevent external sensors from being affected by grounding problems or magnetic fields in the field, we have provided additional grounding support through our electronic boards.

Connection Diagram of Seven Sensors

However, while these measures are solutions we provide as the manufacturer, it is also very important that our customers never overlook the grounding conditions at their own sites.

Proper and effective grounding of the structures where the installation will take place is critical for the safe operation of the product and the prevention of potential malfunctions.