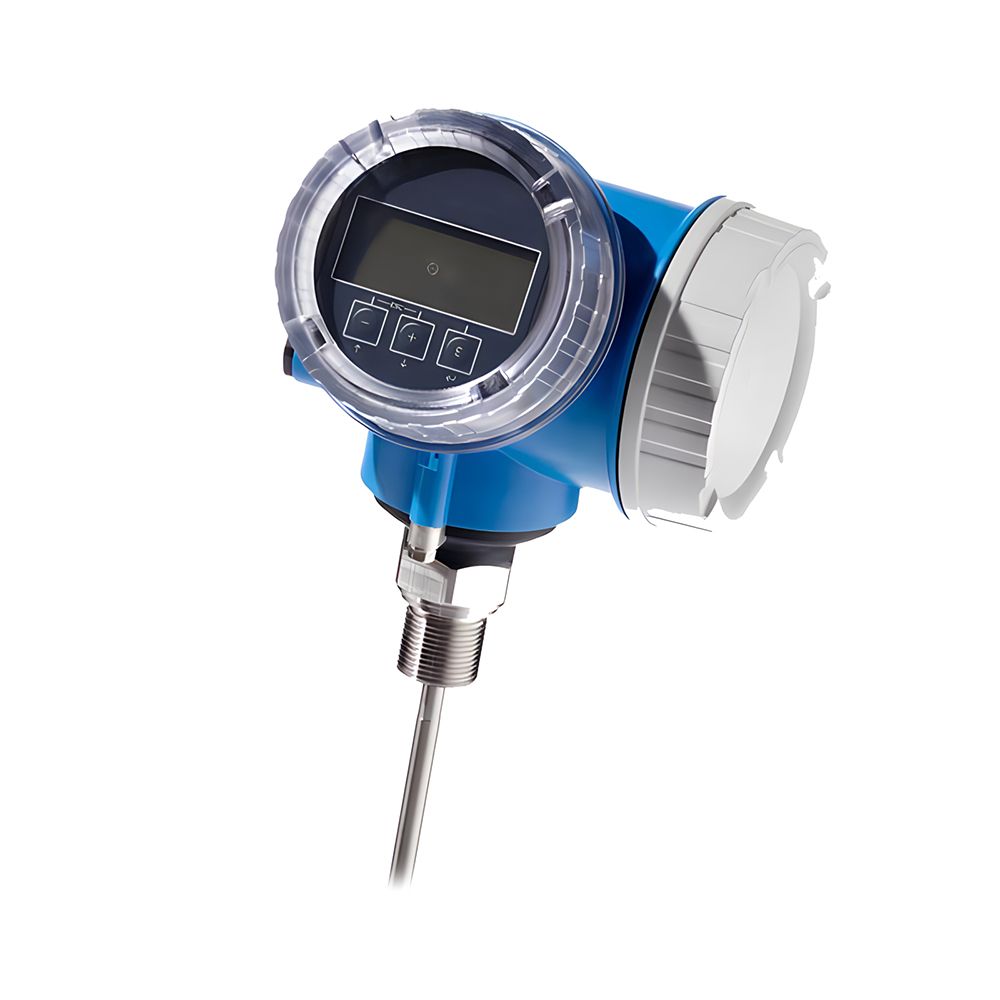

Radar Level Sensor

Radar sensors use radio waves to measure the level of the material. They emit electromagnetic waves and measure the time it takes for the waves to bounce back from the material surface. Radar sensors can provide accurate and reliable measurements even in challenging environments with dust, vapors, or high temperatures.

Radar Level Sensors are suitable for measuring the level of various materials, including solids, liquids, and slurries, in different storage vessels, such as silos, tanks, and containers. They are commonly used in the milling industry for monitoring grain levels, flour, powders, and other materials.

These sensors offer benefits such as high accuracy, reliability, and versatility in challenging environments. They can provide continuous level monitoring and are not affected by factors like dust, vapor, temperature, pressure, or changes in material properties. Radar sensors are capable of measuring levels over large distances and can be used in applications with aggressive or harsh process conditions.

Radar Level Sensors are available in two main types: Non-contact Radar, which uses free-space radar technology, and Guided Wave Radar, which utilizes a waveguide or probe that extends into the material.

Non-contact Radar sensors are suitable for measuring the level of materials without direct contact, offering advantages such as easy installation, minimal maintenance, and resistance to material buildup or coating.

Guided Wave Radar sensors, on the other hand, use a probe that extends into the material and guides the radar waves. These sensors are suitable for applications with more challenging conditions, such as foam, agitated surfaces, or materials with low dielectric constants.

When selecting and installing Radar Level Sensors, it’s important to consider factors such asthe material properties, vessel design, installation requirements, and the specific needs of the milling process. Proper calibration and periodic maintenance are essential to ensure accurate and reliable level measurement.