SEVEN’s 3S-SLS-RP is a compact rotary paddle level sensor for powders and granules in silos, tanks, and bunkers. It runs on 18–30 V DC, provides a dry-contact relay output, and signals status via a red warning lamp. Torque can be set in four levels to match material bulk density. Accessories include a longer shaft and a thermal protection kit for hot products.

SEVEN Sensor Solutions builds reliable silo level sensors with short lead times, local support, and compliance with regional standards. Accurate level signals reduce manual checks, prevent overfills and shortages, and keep production running smoothly.

What problem does a rotary paddle level sensor solve?

In powders and granules, reliable “point level” (empty, low, or full) is hard to verify from the outside. The 3S-SLS-RP puts a small paddle into the product stream; when material presses the paddle, the motor stalls by design and a relay changes state. Operators and PLCs get a clear signal that the level has reached the set point.

How does the 3S-SLS-RP work?

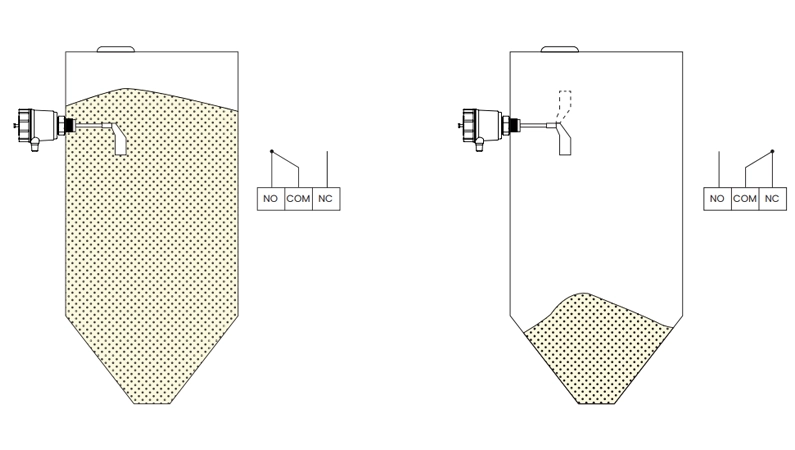

- Free spin: With no product at the paddle, the motor turns freely and the COM-NC path is active. The red lamp flashes.

- Material present: When product loads the paddle, a Hall-effect sensing stage detects stall; the relay switches to COM-NO and the lamp turns solid.

- Material clears: As the paddle is no longer blocked, the motor restarts; COM-NC is active and the lamp returns to flashing.

You can match different products by choosing one of four torque levels on the PCB (LEV1 to LEV4). Use lower torque for light materials, higher torque for denser ones. Note that excess torque on low-density media may cause sweeping instead of stopping.

Where can you use it?

Typical installations include flour, grain, plastic pellets, cement, lime, fly ash, animal feed, and similar bulk solids. Horizontal or vertical mounting is supported; choose a shaft length to suit the material and geometry. The extension shaft helps in deep or vertical applications, and the thermal protection apparatus shields the shaft when measuring hot product with ceramic insulation between paddle and housing.

What are the key specs?

| Feature | Specification |

| Sensor type | Rotary paddle point level |

| Supply | 18–30 V DC (24 V DC recommended) |

| Power inputs | 2 independent terminals (choose either, per site conditions) |

| Output | Relay, ON/OFF, DC max. 125 V / 10 A |

| Rotation speed | 4 rpm |

| Torque levels | LEV1 0.04 N·m, LEV2 0.06 N·m, LEV3 0.11 N·m, LEV4 0.17 N·m |

| Current draw (24 VDC) | LEV1 50 mA, LEV2 70 mA, LEV3 160 mA, LEV4 330 mA |

| Operating temp. | −40 °C to +65 °C |

| Humidity | 0–100 % RH |

| Dimensions / weight | 131 × 103 × 347 mm, ~800 g |

| Materials | Housing polyamide + fiberglass; shaft/paddle chrome |

| Plunge length | 15 cm (longer shaft available) |

| Origin | Türkiye |

| Status lamp | Flashing = running; Solid = paddle blocked/full; Off = no power |

How do you wire and commission it?

Terminals (on the PCB): VIN+, VIN−, COM, NO, NC. Keep sensor cabling separate from AC/DC power runs. Tighten the cover and cable gland to prevent dust and moisture ingress. Use the four-position LEV switch bank to set torque; when multiple buttons are on, the highest level wins (LEV4 > LEV3 > LEV2 > LEV1).

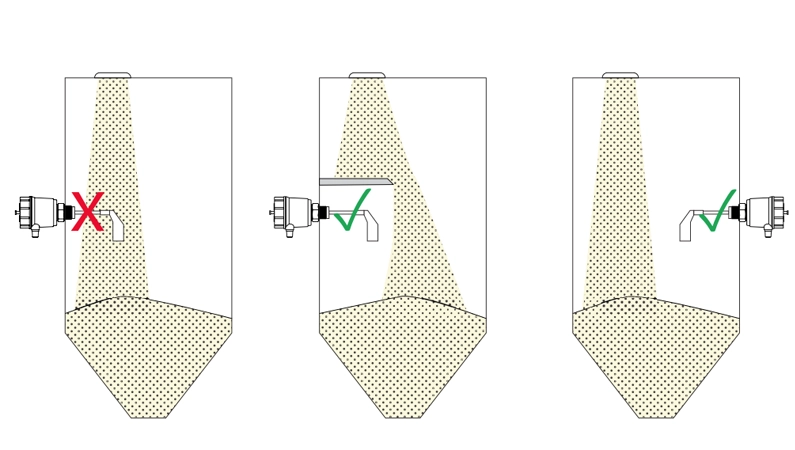

What are the mounting dos and don’ts?

- In horizontal mounting, point the cable gland and warning lamp down to keep water out.

- Avoid spots where build-up can bury or jam the paddle permanently.

- If used as a low-level switch, make sure the paddle is fully covered at the set point.

- During mechanical assembly, keep dust out; use thread-locking fluid on fasteners.

Frequently Asked Questions

1- How do I know which torque level to start with?

Begin with LEV1 or LEV2 for light powders, and increase for heavier products until the paddle stops reliably at set level. Remember, too much torque on light media can cause sweeping.

2- Can I use it on hot product?

Yes. Add the Thermal Protection Apparatus to insulate the shaft with ceramic elements so heat does not migrate to the housing.

3- What does the red light mean?

Flashing = sensor powered and spinning;

Solid = paddle blocked (level reached);

Off = no power.

4- Is there a longer shaft?

Yes. The standard plunge length is 15 cm, and a longer shaft option is available.

5- What maintenance is needed for rotary paddle silo level sensor?

Periodically check fasteners, cable condition, seals, and for moisture or dust inside the enclosure, especially in harsh environments.