What is the SEVEN Capacitive Silo Level Sensor and How Does It Work?

The SEVEN Capacitive Silo Level Sensor is an advanced solution for accurately detecting the levels of solid materials in silos, tanks, and bunkers. With its high detection sensitivity, it enhances operational efficiency, improves workplace safety, and contributes to more reliable processes.

The SEVEN Capacitive Silo Level Sensor detects material levels by utilizing an electrical field created by electrical charges. Based on the adjustable sensitivity level, the capacitance value changes when the material approaches or comes into contact with the sensor, and the information is transmitted to automation systems via the sensor’s relay. To make it easier for users to monitor the system, an indicator lamp on the sensor is provided.

The Indicator Lamp Works in 3 Different Modes:

- Continuous On: The sensor is operating, and the material level has reached the detection limit.

- Flashing Mode: The sensor is operating, and the material level is below the detection limit.

- Continuous Off: The sensor is not operating, and the power supply is disconnected.

The Capacitive Silo Level Sensor must be powered by an external power source. The input power supply is nominally designed for 24 V, but it can also operate with a voltage range of 18 to 26 V DC.

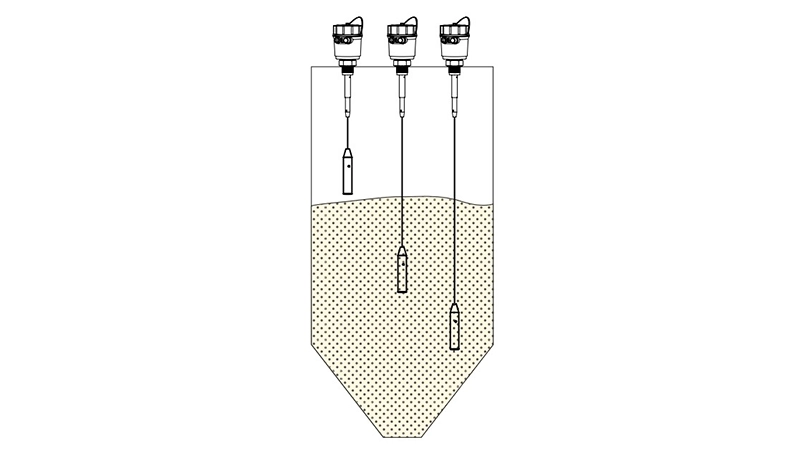

The standard Capacitive Silo Level Sensor rope length is 100 cm, but SEVEN offers an optional adjustable rope length to accommodate different level requirements and silo sizes. This feature allows the sensor to be used in various types of silos and at different detection points.

How should the SEVEN Capacitive Silo Level Sensor be Installed?

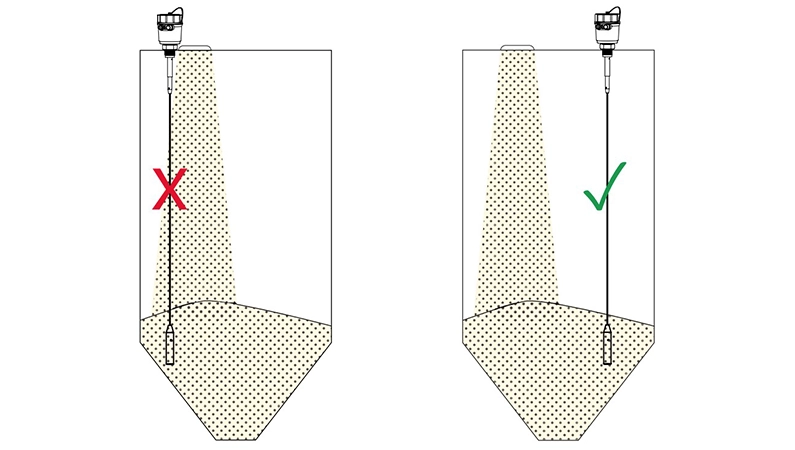

First, you need to decide where to install the product. The sensor’s detection surface should be positioned so that it does not come into direct contact with areas where the product to be filled may accumulate, and it should not be too close to the filling area. Additionally, water ingress into the sensor should be strictly avoided.

Once the installation location is decided, the mounting should be done correctly as shown in the image below.

Why Should We Use a Silo Sensor?

- Optimum Inventory Usage: Proper monitoring of silos ensures uninterrupted material supply, preventing both stockouts and overstocking. This keeps production schedules on track and costs under control.

- Risk Reduction: Traditional silo level monitoring methods usually require manual checks, which can expose workers to risks such as falls or harmful dust inhalation. SEVEN Silo Level Sensors eliminate the need for manual checks, enhancing workplace safety. Workers do not need to climb silos, and accurate data is provided, significantly reducing the risk of accidents and injuries.

- Real-Time Data: The material levels can be continuously monitored, and refilling operations can be carried out in time when necessary. This information allows production schedules to be more accurately adjusted according to raw material supply, reducing work interruptions and improving resource efficiency.

- Early Detection of Faults: Sensor data enables the early detection of equipment malfunctions or maintenance needs, reducing unexpected issues and costly repairs.

- Sustainable Environment: By reducing the frequency of material deliveries, it helps to decrease emissions related to transportation and contributes to a more sustainable supply chain. The data-driven approach ensures effective use of resources, minimizes waste, and contributes to achieving environmental goals.

Why Should SEVEN Capacitive Silo Level Sensor Be Preferred?

- Accurate and Reliable: Provides accurate and reliable real-time monitoring of fill levels.

- Easy Installation: Easily integrates into existing industrial systems.

- Enhanced Safety: Eliminates the need for manual silo checks, reducing workplace risks and hazards.

- Optimal Material Usage and Lower Costs: Optimizes material usage and reduces operational costs by preventing overfilling.

Frequently Asked Questions (FAQ)

1- What is the rope length of the capacitive silo sensor?

The standard length is 1 meter or 2 meters, but SEVEN offers an optional adjustable rope length to accommodate different level requirements and silo sizes.

2- What is the delivery time?

The delivery time for orders of 1 to 5 units is 2-3 weeks.

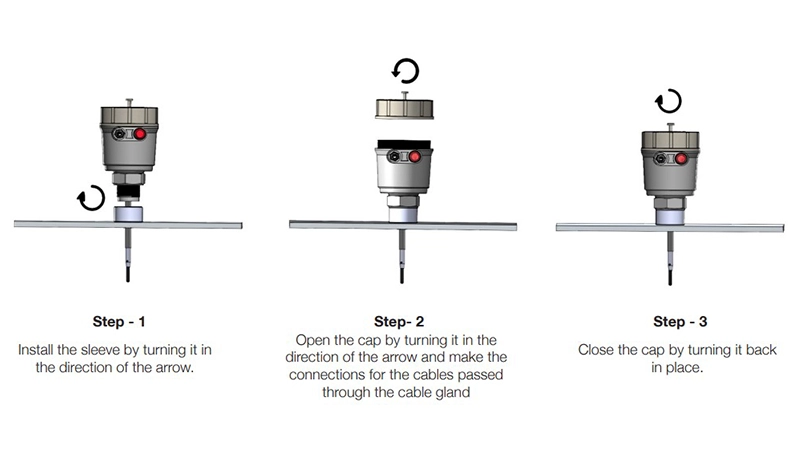

3- How is the installation done?

You can refer to the user manual for installation. The link is:

https://sevensensor.com/files/d/tr/3S-SLS-CA_Kullanici_Kilavuzu.pdf

4- How does it work?

The SEVEN Capacitive Silo Level Sensor detects material levels using an electrical field, and when the material approaches or touches the sensor, the capacitance value changes. This change is transmitted to automation systems through the sensor’s relay, and users can easily monitor the status through the indicator lamp on the sensor.

5- What are the advantages?

The advantages of using the silo sensor include optimum inventory usage, risk reduction, real-time data, early fault detection, and a sustainable environment.