When it comes to solar energy systems, even small environmental changes can have a measurable impact. One of the most common issues is soiling. Over time, dust, sand, pollen, and other debris build up on the surface of solar panels and reduce their ability to absorb sunlight. While it may not look serious, this layer of grime can cause significant energy losses if left unmanaged.

That is where soiling sensors come in. These devices help solar plant operators monitor how dirty panels are getting and decide the best time to clean them. With reliable data, it is possible to schedule cleanings only when truly needed, save on water and labor, and keep energy output steady.

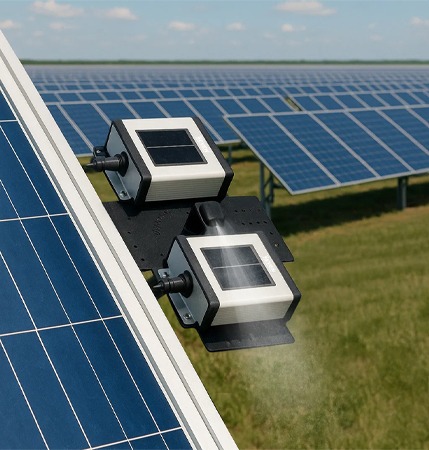

SEVEN, a leader in PV monitoring equipment, offers a range of soiling sensors suited for different needs.

What Is a Soiling Sensor?

Soiling sensors, sometimes called dust sensors, are tools designed to measure how much dirt has accumulated on the surface of solar panels. This buildup blocks sunlight from reaching the photovoltaic cells and can lower energy output. If the soiling ratio read from the sensor is 10%, it means that there is a 10% energy loss in the facility.

Soiling Ratio = Energy Loss

These sensors typically work by comparing the Irradiance received by the clean reference cell with the soiled one, which is in the same state as the installed panels. The difference between the two helps to determine the soiling ratio, in other words, how much power is being lost due to dirt.

Whether you want to fine-tune your maintenance plan or improve your energy yield reporting, understanding how soiling sensors function is essential to making smarter decisions about your solar system.

But before we compare sensor types, let’s look at why monitoring soiling is such a crucial part of system performance.

Why Monitoring Soiling is Important?

Keeping track of soiling levels is not just about knowing when panels are dirty — it is about protecting your investment and getting the most from your system.

Even a small layer of dust or grime can reduce panel efficiency by 5–20%, depending on the environment. Without proper monitoring, you may not notice the drop in output until it has already caused a measurable loss.

By using soiling sensors, operators can clean panels when it is actually needed, not just according to a fixed schedule. This reduces unnecessary cleanings, saves water, lowers labor costs, and prevents performance losses. It also helps spot other issues, like sudden changes in dirt levels that could point to nearby construction, wind-blown debris, or equipment malfunctions.

In short, soiling monitoring helps optimize performance, cut operating costs, and extend the life of your solar installation.

SEVEN offers a wide range of Soiling Sensors

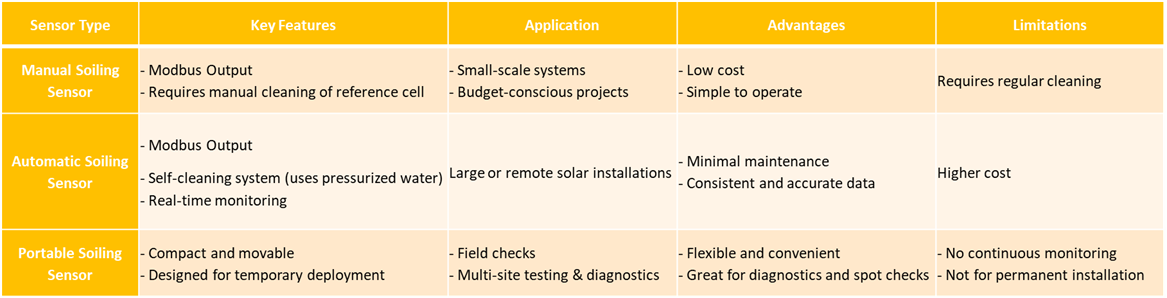

If you are trying to decide between a manual, automatic, or portable soiling sensor, SEVEN has all three, and each serves a different purpose depending on what your site needs.

Manual sensors are the most straightforward. They need someone to clean and check them regularly, which keeps the cost low and the setup simple.

Automatic sensors do the heavy lifting for you. They track soiling levels around the clock and do not need daily attention, which makes them a great fit for larger plants or remote locations where regular maintenance is tricky.

Then there are portable sensors. These are ideal if you need flexibility, or if you are handling site inspections, spot checks, or managing multiple locations. They are easy to carry, quick to use, and give you the numbers you need without any permanent installation.

The following table summarizes the differences between the models of Soiling Sensor SEVEN offers.