When installing, troubleshooting, or verifying sensor data, the right Modbus testing tool can save hours of effort. Based on real-world testing, this guide compares three tools for working with SEVEN Sensors with Modbus RTU output:

- SEVEN Configuration Tool (GUI)

- Modbus Poll

- ModScan

Why Choose the SEVEN Configuration Tool for Sensor Setup?

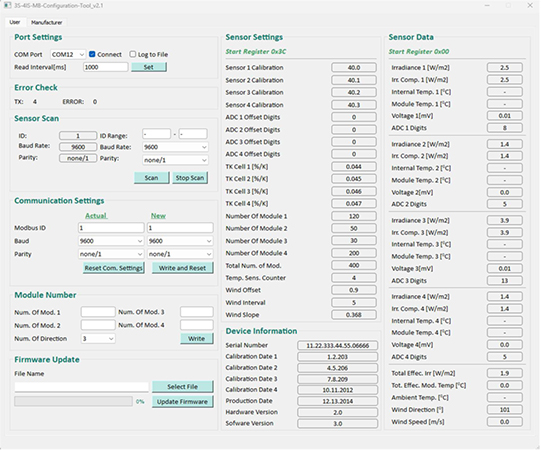

The SEVEN Configuration Tool is the most efficient and user-friendly option for configuring SEVEN Sensors. It is clean, intuitive, and made specifically for each SEVEN sensor model. Currently available for Windows, each version of the tool is tailored to the sensor’s features and register layout.

Why It is Great for SEVEN Sensors

- Predefined data labels (e.g., Temperature °C, Irradiance W/m²) remove the need to reference external Modbus maps.

- Supports Modbus RTU and Modbus TCP.

- Built-in hex view with signed/unsigned formatting.

- Uses 0-based register addressing, perfectly aligned with SEVEN’s official Modbus documentation.

- Allows you to change key parameters like Modbus ID, baud rate, and parity through a simple menu. So, no need to send Modbus write commands manually.

- Allows you to update the Software of SEVEN Sensors when needed.

Real-world Example

Testing a weather station? The tool already knows what each register represents. You don’t have to match register 30006 to “Irradiance”, for example, as the interface does it for you.

Need to change Modbus ID to 5, the Baud Rate to 19200, and the Parity to “even”? Just write them in the “new parameters” section.

No register math, no coding: just quick, error-free configuration.

How Does Modbus Poll Help with Advanced Diagnostics?

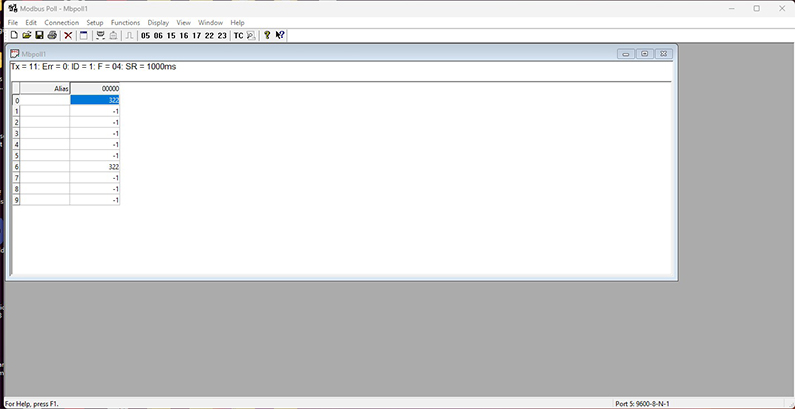

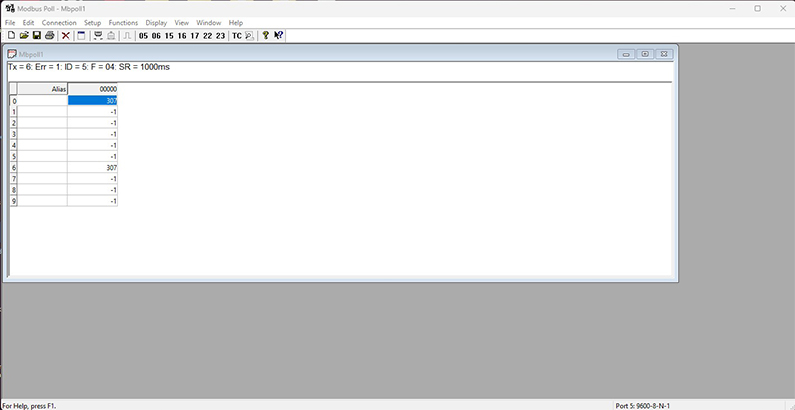

Modbus Poll by Witte Software is a diagnostic powerhouse for engineers who want full control. It supports RTU and TCP, and lets you simulate a Modbus master, test multiple devices, and monitor data in real-time.

Why Modbus Poll Works for SEVEN Sensors

- Excellent for advanced debugging and scaling validation.

- Multi-slave support makes it useful for testing arrays of sensors.

- Uses 0-based register addressing, which matches SEVEN documentation directly.

Limitations of Modbus Poll

To change sensor parameters like Modbus ID or baud rate, you have to manually write values to the correct holding registers.

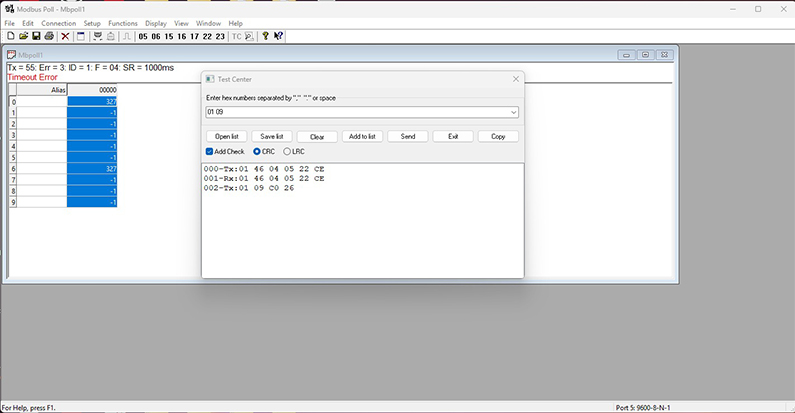

Example: Changing Modbus ID with Modbus Poll

To change Modbus ID of SEVEN Sensor from 1 to 5:

- Go to “Functions > Send Custom Message”

- Build the command using Function Code 0x46 (Read & Change Parameters) with Subfunction 0x04:

01 46 04 05

01 09

-

- 01: current device address

- 46: function code for extended config

- 04: subfunction for changing ID

- 05: new Modbus ID

- 01 09: apply changes

You can also write directly to Holding Register 40109 with value 5 (new Modbus ID), using Function Code 0x06 (Write Single Register). In this case, set address to 40109 (or 108 if you are using Modbus Poll’s offset option).

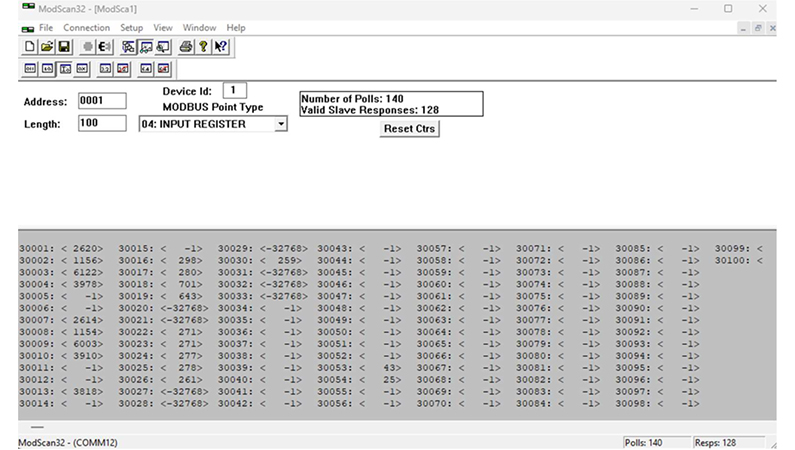

When Is ModScan the Best Choice?

ModScan, from WinTECH Software, is ideal for quick register checks in the field. It runs fast, uses little memory, and supports RTU, TCP, and ASCII protocols.

Why Modscan is Handy

- Ideal for verifying wiring and communication.

- Displays data in multiple formats (decimal, hex, binary).

- Requires little setup.

Important Note on Addressing in Modscan

ModScan uses 1-based addressing, which means:

If SEVEN’s documentation says a value is at register 30006, you need to enter 30007 in ModScan.

This difference is easy to miss and can cause confusion when comparing data across tools.

Changing Sensor Settings in ModScan

To change something like baud rate or Modbus ID, you must manually write to the appropriate holding register.

To change baud rate from 9600 to 19200:

Use the Function Code 0x46, Subfunction 0x06, with values:

- Baud Rate Value for 19200: 02

- Parity/Stop Bit for Odd: 02

So your raw command (in hexadecimal) would be:

01 46 06 02 02

Steps:

- Go to Command > Send Custom Message

- Paste the above hexadecimal string

- Click “Send”

Then you must send another command to write the device address (if also changing ID), followed by a restart command:

- Restart command (0x08):

01 08 00 00 00 00

Always make sure you know the correct register and value, as a wrong write could break communication.

Comparison Table: Modbus Tools for SEVEN Sensors

| Feature / Tool | SEVEN Configuration Tool | Modbus Poll | ModScan |

| Primary Purpose | Sensor setup and configuration | Sensor testing, diagnostics | Quick checks and simple polling |

| User Interface | Graphical, sensor-specific GUI | Tabbed, detailed | Minimal, compact |

| Modbus Protocols | RTU, TCP | RTU, TCP | RTU, ASCII, TCP |

| Register Addressing | 0-based | 0-based | 1-based |

| Parameter Configuration | Simple & easy | Manual write to holding registers | Manual write using function codes |

| Predefined Labels | Yes | No | No |

| Hex/Signed View | Yes | Yes | Yes |

| Multi-Sensor Support | Per sensor model | Yes | No |

| Live Data Monitoring | Yes | Yes | Yes |

| Logging & Diagnostics | Basic | Advanced | Minimal |

| OS Support | Windows only | Windows only | Windows only |

| Licensing | Free | Paid (trial available) | Paid (trial available) |

| Best Use Case | SEVEN sensor commissioning | Debugging or advanced diagnostics | Quick register value checks |

What Safety Practices Should You Follow?

- SEVEN Configuration Tool includes built-in protection via preloaded maps, but with other tools, always verify the register map first.

- Avoid hot-plugging RS-485 connections.

- Use USB isolators to protect your ports from electrical noise.

- Document all register addresses and configuration values during commissioning.

Each tool has its place, but only SEVEN Configuration Tool is made specifically for SEVEN sensors:

- SEVEN Configuration Tool: Purpose-built for speed, accuracy, and safety. So, no manual entries, no offsets, no confusion.

- Modbus Poll: Excellent for experienced users needing full register control and detailed diagnostics.

- ModScan: Great for fast, one-off checks, but limited and prone to offset errors if you are not careful.

If you are working with SEVEN sensors, there is no better tool than the one made for them.

Frequently Asked Questions (FAQ)

Q: Which tool is best for first-time SEVEN sensor setup?

A: The SEVEN Configuration Tool—it’s purpose-built, user-friendly, and avoids addressing confusion.

Q: Can Modbus Poll change baud rate and Modbus ID?

A: Yes, but only by manually writing to the correct registers.

Q: Why does ModScan show different register numbers?

A: Because it uses 1-based addressing, values appear shifted by one compared to SEVEN’s documentation.