Electricity generation from solar energy is made possible through the photoelectric effect. Looking back at the history of science, we see that this phenomenon came to light and began to be developed in the early 20th century, when scientists focused their research on the photoelectric effect.

As a result of these developments, solar power plants began to emerge, and systems that convert solar energy into electricity started to be implemented.

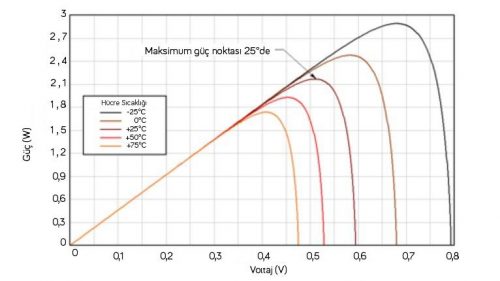

Experiments conducted on these systems revealed that, under the same irradiance, the amount of energy produced varied depending on the temperature.

The irradiance value that results from the temperature difference between the reference cell and its surrounding environment during measurement is called temperature-compensated irradiance.

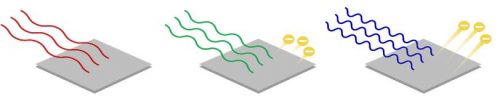

The Photoelectric Effect and Irradiance

These differences can be detected thanks to irradiance sensors equipped with reference cells, which are used to measure the amount of solar radiation. Thanks to the reference cell integrated into the irradiance sensor, sunlight falls directly onto the cell, triggering the photoelectric effect. This process generates an electric current at the output of the cell. Not all solar energy is converted entirely into electrical energy. The portion of solar energy that isn’t converted into electricity transforms into heat and is released into the surrounding environment. Thermal changes caused by the photoelectric effect occur on the reference cell, resulting in a temperature difference between the irradiance sensor and its surrounding environment. Under standard test conditions, the ambient temperature is assumed to be 25°C. When measuring irradiance at temperatures below or above this value, temperature compensation must be taken into account. When calculating the temperature-compensated irradiance value, both the temperature parameter and the temperature coefficient of the reference cell should be considered.

Why Is Temperature Compensation Important?

In solar power plants, accurate performance evaluation depends on comparing the energy produced with the expected output. To make this comparison reliable, irradiance data must come from a sensor that accounts for temperature compensation. Without this adjustment, irradiance values will be incorrect, leading to inaccurate performance ratio (PR) calculations and potentially misleading plant operation decisions.

At SEVEN Sensor, our radiation sensors are designed and calibrated in accordance with IEC-60904 and IEC-61724 standards. They are built to deliver precise and temperature-compensated irradiance data—helping solar plant operators monitor performance with confidence. For more detailed information about our radiation sensors, please visit our website.