When you are running a solar or environmental monitoring system, getting accurate and reliable sensor data is absolutely key. SEVEN sensors, whether they are tracking irradiance, module temperature, wind speed, or back-of-module Temperature, all rely on clean, interference-free communication to deliver real-time data to your data logger or SCADA system.

But here is a common mistake that trips up a lot of installations: running the RS-485 communication cable for SEVEN sensors in the same conduit or cable tray as AC or DC power cables. It might seem harmless, but that kind of setup can cause all sorts of problems, from glitchy sensors to total data loss.

The Core Issue: Electrical Noise and Interference

AC and DC power cables carry high voltage and current, and they often involve switching devices like inverters and relays. These can generate electromagnetic interference (EMI) or radio frequency interference (RFI). That invisible “electrical noise” can:

- Leak into nearby data lines

- Scramble Modbus signals sent over RS-485

- Cause CRC errors, communication timeouts, or endless retries

- Lead to unstable or completely failed communication

Now, RS-485 is built for industrial environments and is fairly rugged, but it still needs to be installed correctly. When placed too close to power lines, it is vulnerable.

What Happens When You Don’t Separate the Cables

Here is what you might run into if your SEVEN sensor cable is too close to AC or DC power cables:

- The data logger doesn’t receive anything

- You get unstable, jumpy, or missing readings

- Communication ports on inverters get blocked due to signal collisions

- You waste hours (or days) troubleshooting

- You risk voiding your warranty over poor installation

How to Avoid These Headaches

Here is how to keep your sensor network healthy and your headaches to a minimum:

1. Use Separate Conduits or Cable Trays

Keep your RS-485 communication cables away from AC and DC power lines.

A good rule of thumb is at least 30 cm (12 inches) of separation.

And whatever you do, don’t bundle power and signal cables together.

2. Use Shielded Twisted Pair Cables for RS-485

All the cables provided by SEVEN are shielded twisted pair cables which help block out EMI.

Just make sure you ground the shield at one end only, preferably at the data logger side.

3. Avoid Long Parallel Runs

If you must cross AC lines, do it at a 90-degree angle. That minimizes interference.

4. Label Everything Clearly

Clearly label your SEVEN sensor cables: Although they are labeled, but when using cable shield an extra label must be arranged

It makes future maintenance much easier.

Also, keep your cable paths and sensor IDs documented: your future self will thank you.

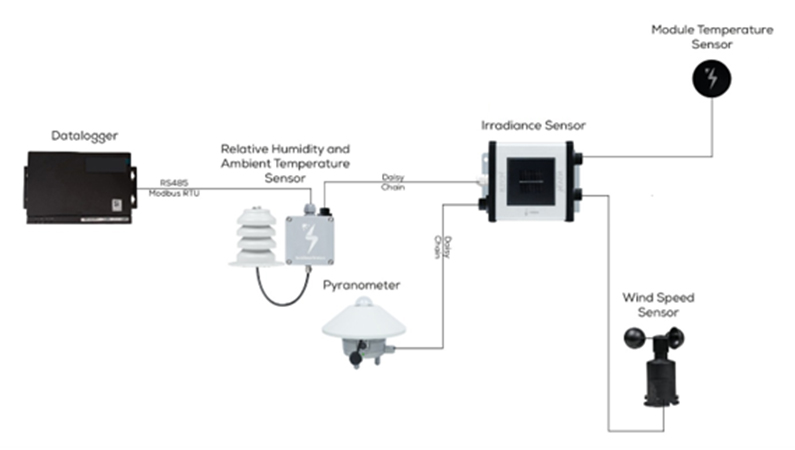

SEVEN Sensor System Overview

Each SEVEN sensor uses RS-485 Modbus RTU and can be daisy-chained with others. The whole system depends on:

- Clean signal transmission

- Consistent address polling

- Minimal data errors

If just one sensor gets hit by electrical noise, it can disrupt the entire chain.

Real-World Example: SEVEN Sensor in India

At a 10 MW solar site in India, they kept losing Soiling and temperature data. After a few days of troubleshooting, they discovered the SEVEN sensor cables were installed in the same tray as 600 VDC combiner box wiring. Once they rerouted the cables with proper separation, the system stabilized and communication returned to normal.

Keeping power and communication cables separate is not just a best practice, it is essential to system performance and long-term reliability.

Doing it right means:

- Your data stays accurate

- You minimize downtime

- You save time on troubleshooting

- You protect your monitoring investment

If you are ever unsure, just play it safe and route signal cables far from power lines. That simple step can prevent a lot of problems later on.