In modern industries, efficient material handling is essential for maintaining productivity and ensuring workplace safety. Silos that store bulk materials such as grains, granules, and pellets must be carefully monitored to prevent costly issues like spillage, overfilling, and production downtime. This is where silo level sensors play a critical role.

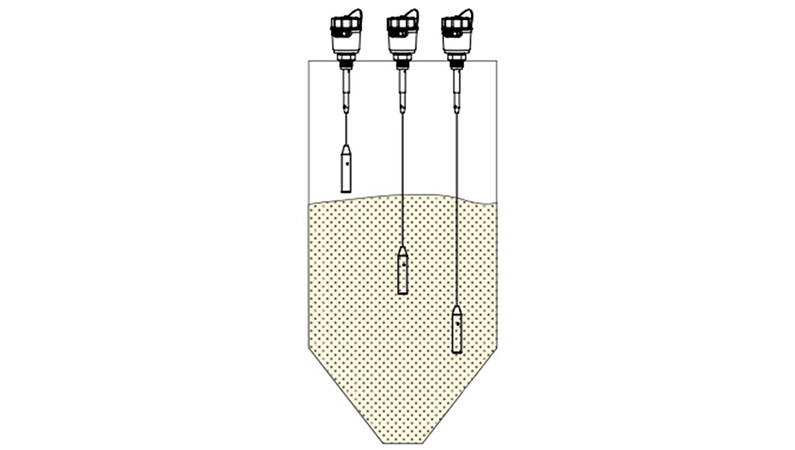

The SEVEN Capacitive Silo Level Sensor offers a practical solution for keeping an eye on the fill status of bulk materials such as powders, grains, or pellets. Built for durability and accuracy, the sensor works across a range of storage setups including silos, tanks, and bunkers. Here’s how it works and why it is a valuable addition to industrial processes.

How Does SEVEN Capacitive Silo Level Sensor Work?

The SEVEN Capacitive Silo Level Sensor detects material levels by utilizing an electric field created by electric charges. The sensor uses a capacitive measurement principle. When bulk material comes near the sensor probe, it causes a shift in capacitance value. Once this happens, the sensor sends a signal through its relay, which can be picked up by an automation or monitoring system. A built-in light also gives local status feedback:

- No light — Power is off

- Blinking light — Material is below the sensor’s detection point

- Solid light — Material has reached the set fill level

Key Features of SEVEN Capacitive Silo Level Sensor

- Automation Ready: Can be integrated into existing systems for automatic level monitoring.

- Flexible Installation: Supports a variety of rope lengths, making it easy to fit into different silo sizes.

- Non-Contact Sensing: Detects material levels without direct physical contact, which helps reduce wear on components.

Why Choose SEVEN Capacitive Silo Level Sensor?

- Accurate and Reliable: Provides real-time and precise fill level monitoring.

- Easy Installation: Simple integration into existing industrial setups.

- Enhanced Safety: Eliminates the need for manual level inspections, reducing workplace hazards.

- Cost-Effective: Reduces operational costs by optimizing material usage and preventing overfills.

By adopting SEVEN Capacitive Silo Level Sensor, industries can improve their operational efficiency, reduce risks, and ensure sustainable resource management. As technology advances, smart silo monitoring solutions like SEVEN’s capacitive sensor will continue to play a crucial role in modern manufacturing and logistics.