The utilization of solar photovoltaic plants has grown significantly in recent years, and it is expected to increase even more in the future. As a result, the need for better maintenance and monitoring systems is becoming increasingly important. One of the biggest challenges faced by PV plants is soiling, which is the accumulation of dirt, dust, and other debris on the surface of solar panels. This accumulation can significantly decrease the efficiency of the PV panels, reducing the overall power output of the plant. To address this issue, SEVEN has developed a wide range of soiling sensor models.

How Is the Soiling Ratio Calculated by SEVEN

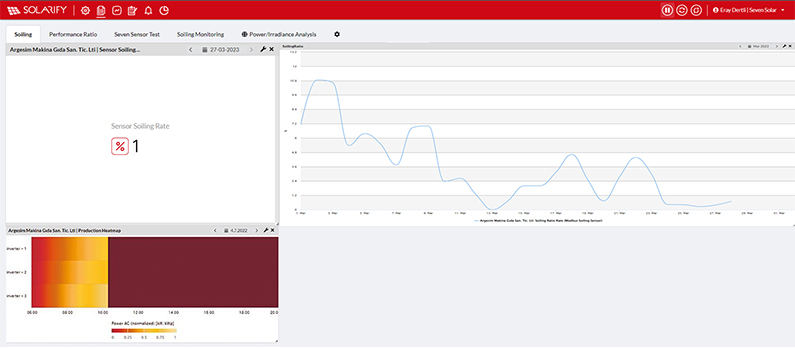

SEVEN developed many models of Soiling Sensor by adopting the same principle of calculating the Soiling Ratio. The method SEVEN is following is by comparing the output of two irradiance sensors; one reference irradiance sensor which is cleaned periodically and the other one cleaned simultaneously to the panels in the plant. By following the Standard IEC61724-1, the soiling ratio is calculated daily. The following Formula explains simply what the soiling ratio refers to.

![]()

The Soiling Monitoring Sensor of SEVEN is able to calculate all types of soiling affecting the performance of the PV Panels. As the used Irradiance Sensors are kind of mini panels, the effect of soiling on their output would be equal to the effect of the soiling on the output of the panels. The soiling ratio is equal to the Power Loss in a plant as per the made research.

Models of Soiling Monitoring System by SEVEN

The requirements of clients differ but the purpose is the same; getting the soiling ratio of the PV Plant to avoid a significant power loss. Thus, SEVEN developed different models as per the market needs.

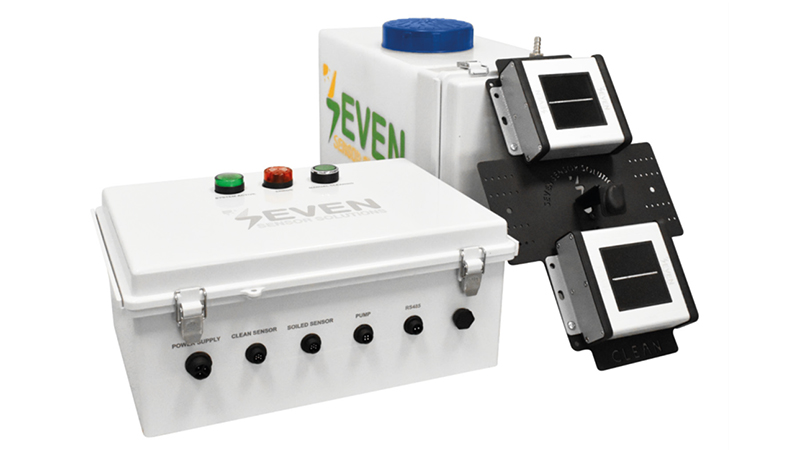

Automatic Soiling Sensor

The first question that comes to mind is how is the reference irradiance sensor cleaned. It is obvious that the user always prefers the easiest way to run a system, which is automatic cleaning in this case. In another hand, sometimes manual cleaning can be time-consuming and can pose safety risks for the workers involved, especially for difficult-to-reach locations. Thus, SEVEN provides the full system of automatically cleaned Soiling Sensor. The operator has only to fill the water tank with Pure Water, with antifreeze, when required, twice per year. In fact, the water tank included in the Automatic Soiling System has a capacity of 18 lt, which is enough to run the system for 6 months. The whole system can be installed in minutes with a single person and requires AC power (220v) to be powered. The cleaning is performed by a nozzle installed above the reference irradiance sensor and the cleaning time is defined in the firmware by following the standard IEC61724-1.

Manual Soiling Sensor

Although automatic cleaning would be the best choice for any user, but the limited budget in some projects makes the user unable to afford the cost of this model. Thus, the manual cleaning option is available. In the Manual Soiling Sensor model, both irradiance sensors are combined in the same box with mounting facilities, which makes it easy for the operator to mount in fastly in the plan of array of the panels. As for the cleaning, it is done manually by an operator on-site by using a glass cleaning wipe.

Monitoring Methods of the Soiling Ratio

After having decided on the cleaning method, it is time to decide how to get the data from the soiling sensor to monitor the system. In general, the plant’s performance is controlled through a monitoring system by using a SCADA system or simply through the monitoring system of the datalogger itself. That is why the Modbus Output option is, usually, the most suitable way to monitor the soiling ratio. SEVEN provides the Modbus RTU Output, regardless the cleaning method, which is compatible with well-known brand dataloggers and all PLC & SCADA systems with RS485 Port. The distance between the Soiling Monitoring Sensor and the datalogger or PLC can be up to 1200m without any loss of data.

In some projects, the user prefers to monitor the soiling ratio on-site by using an HMI-PLC which is the second option SEVEN offers. The HMI-PLC allows the user to check the daily calculated soiling ratio on-site by simply checking the displayed value on the screen. The other feature that can be added to this model, upon request, is the alarm system. So, if the user wants to receive a warning when the soiling ratio reaches a certain level, this can be added while programming the PLC.

The benefits of SEVEN Soiling Sensor

In general, the benefit of soiling sensors is that they help plant operators optimize their cleaning schedules. By providing real-time data on the soiling ratio, these systems enable operators to determine the frequency of cleaning that is necessary to maintain optimal energy production. This not only improves overall plant performance but also extends the life of the PV panels themselves.

In addition, by helping to improve energy production and reduce maintenance costs, soiling monitoring systems can help solar PV plant operators achieve a faster return on investment. They are an important tool for any plant operator looking to maximize the efficiency and profitability of their solar PV plant

As for SEVEN Soiling Sensor, it is preferred by the clients thanks to its flexibility, easy operation and the diversity of available options, as well as the high quality of both products and after-sales service. SEVEN team never lets the customer with unanswered questions or with a faced problem without a solution.