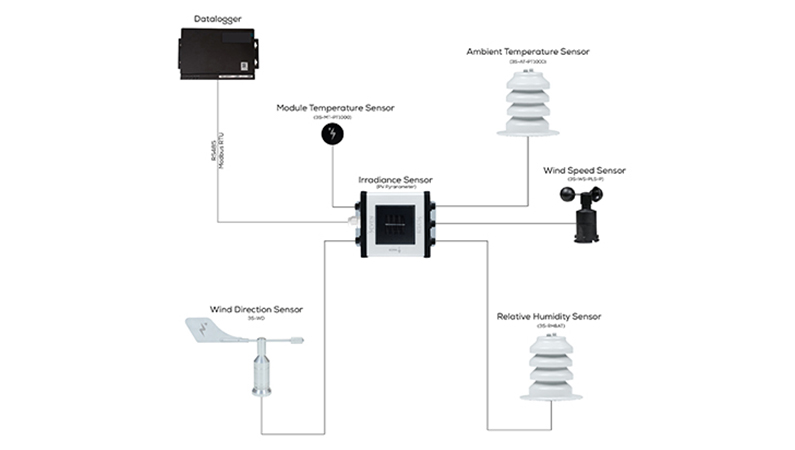

When it comes to solar power plants, performance is everything. To accurately calculate a plant’s performance ratio, it’s essential to gather real-time meteorological data — and that can only happen with the right sensors. Without this data, it’s impossible to carry out a meaningful performance analysis.

Key Data Points for Performance Evaluation

- Irradiance

- Panel surface temperature

- Ambient temperature

- Wind speed

- Wind direction

- Relative humidity

Why Is Ambient Temperature Monitoring So Important for Solar Plants?

The relationship between temperature and photovoltaic (PV) performance is direct and measurable: as the module temperature rises, output decreases. PV panels typically convert just 5–25% of incoming solar energy into electricity. The rest turns into heat, which raises the panel’s surface temperature. The gap between ambient temperature and module temperature varies based on sunlight intensity. The higher the module temperature, the lower the power output. These temperature-related losses are primarily driven by the cell temperature: when the air heats up, so do the cells — and this leads to reduced energy production. (When temperature rises, short-circuit current increases slightly, but open-circuit voltage drops — reducing overall performance.)

Inverters, just like PV modules, are sensitive to temperature fluctuations. As temperatures climb, inverters begin to throttle their output to prevent overheating. This self-protection mechanism, known as power derating, reduces inverter power step by step to safeguard internal components. In normal conditions, inverters operate at full capacity, constantly adjusting to find the Maximum Power Point (MPP). At this operating point, the balance between PV voltage and current delivers maximum power output. This point constantly changes depending on the irradiation levels and the PV module temperature. Maintaining proper thermal conditions prevents the sensitive semiconductors in the inverter from overheating. When the temperature of the inverter’s continuously monitored components reaches a certain threshold, the inverter automatically shifts to a reduced power level. The inverter will gradually reduce output. And in extreme cases, shut down entirely to prevent damage. Once temperatures return to safe levels, the inverter resumes normal operation.

Temperature build-up behind PV panels is strongly linked to their ventilation. Poor airflow behind the panels traps heat, which leads to performance losses. Proper spacing and mounting that allow air circulation are essential for efficient cooling and stable output. In short: Temperature affects both PV modules and critical equipment like inverters. If you want reliable energy yield estimates with minimal uncertainty, ambient temperature must be measured accurately. That’s why Seven Sensor offers high-precision PT1000 Ambient Temperature Sensors.

Thanks to the ambient temperature sensor, you can easily monitor and analyze performance losses caused by heat. Rising outdoor temperatures are directly linked to higher module temperatures, which impact power generation. To fully understand these effects, it’s crucial to measure ambient temperature regularly and with precision.

Curious to learn more? Check out our other articles on the role of temperature in solar power generation: