Deserts are considered the best solar insolation areas, where the highest yearly solar insolation, however high levels of dust. Dust consists of visible and invisible, floating and fallen particles of solid material, such as bird droppings, deposition of dusts and water stains.

Dust accumulation on solar photovoltaic (PV) modules prevents part of solar irradiance from reaching solar panels, which reduces photon absorption and thus contributes in performance reduction of PV systems. It is proved that when PV modules are kept uncleaned for 6 months, their power decreases by around 50%. As a result, there will be a major drop in solar efficiency which will affect directly on revenue. This led us to one fact that cleaning the solar panels is essential!

How do you choose the proper method for cleaning the PV Cells?

The method of cleaning the modules depends on many factors:

- types of modules

- tilt angle installation

- distance between arrays

- water availability

Solar Panels cleaning methods

1. Manual method: For rooftops and smaller installations.

2. Semi-automatic: workers using tractors equipped with rotating brushes for larger scale projects.

3. Fully automatic (robotics): the highest capital cost, but involves no manual laborers except a single user for the largest scale projects.

When do the PV modules have to be cleaned?

The cost of cleaning the solar panels is high, especially in large scale solar plants.

For this, the cleaning process has to be in a specific critical time.

It’s hard to predict the exact time for cleaning the modules. Seven soiling system came to solve this major problem; it’s very important to monitor the soiling ratio and clean the panels accordingly.

![]()

We applied IEC 67124-1 standards for our soiling system, which includes:

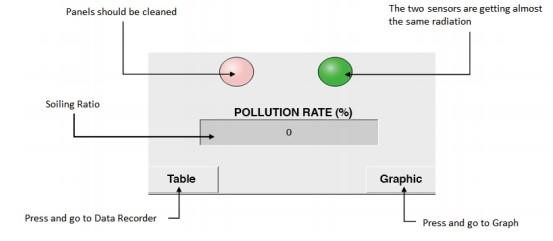

- Two photovoltaic cells are represented by two seven irradiance sensors, one is left to accumulate soil in the same conditions as the PV plant panels, and the other is cleaned periodically manually or automatically as per the model. The two irradiance sensors receive solar irradiation from the sun (W/m^2). Then, the obtained data is transferred to the PLC via an RS485 Modbus RTU cable, which will measure the difference between the data obtained from the two sensors at each point in time and then give the daily average Soiling Ratio.

- HMI programmable logic controller. Once the soiling ratio is measured between the two sensors and reached a certain soiling ratio specified by our customer, the red LED lights up to warn the user to clean the panels. Otherwise, the green LED lights up. The light will appear on the PLC screen as below.

It’s worthy to mention that our soiling system is tested before shipping it to the customer and calibrated by using a reference cell calibrated by Fraunhofer-Institut für Solare Energiesysteme ISE, Germany.