SEVEN Sensor Solution has an SMT Assembly Line. At SEVEN, the electronic boards for all our sensors are manufactured in-house. This production process ensures that our sensors are produced quickly and reliably. So how does SEVEN Sensor Solution carry out these electronic board production processes? This article details the assembly processes.

What is SMT (Surface-Mount Technology) Assembly?

Assembly is the process of placing electronic components onto a circuit board in a specific order.

SMT (Surface-Mount Technology) assembly refers to the process of placing and soldering surface-mount electronic components (SMD components) onto a circuit board. SMD components are placed onto the PCB automatically or manually onto the correct pads.

How to Perform Manual SMD Placement?

Newly designed electronic PCB boards undergo manual placement during the initial testing phase. When performing manual placement, extreme care and precision are required. The most important factor here is to keep your hands steady. The components to be placed are listed by the designer. Their locations on the PCB are also clearly marked.

Manual soldering;

- PCBs (circuit boards) are prepared.

- A stencil suitable for the board (a thin metal template with holes that align exactly with the pads to be soldered) is placed on the board.

- Solder paste is applied to the required areas on the board using a spatula.

- SMD components are carefully placed onto the solder paste using SMD tweezers, referring to the design list. It is important to note that we must use the correct materials. Incorrectly placed materials can cause errors on the board.

- SMD components must be placed with attention to their orientation.

- Once all components are correctly placed, the board is heated in an SMT reflow oven; this melts the solder paste and bonds the components to the board.

To test the boards coming out of the SMT reflow oven, the component leads are connected and current tests are performed. The boards that undergo current testing are delivered to the designer. The boards that pass the tests performed by the designer are ready for mass production.

Mass production is carried out by the SMT PLACEMENT MACHINE.

How to Perform Assembly Using an SMT (Surface-Mount Technology) Assembly Machine?

SEVEN Electronic Card

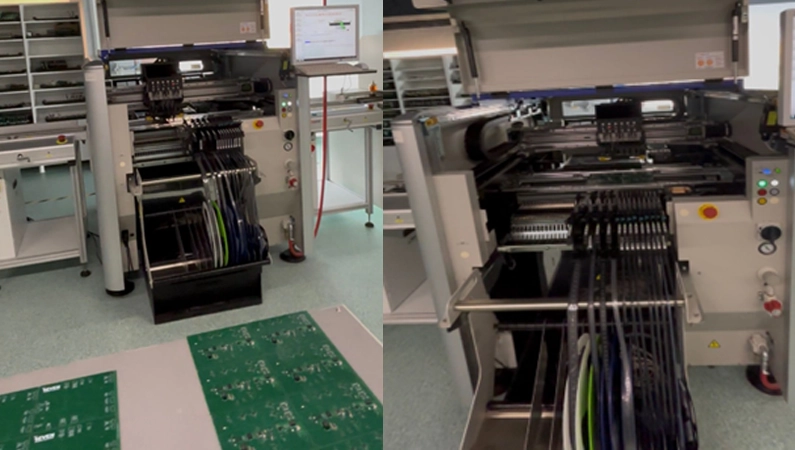

An SMT placement machine is an automatic device that places SMD components onto PCBs (printed circuit boards) coated with solder paste very quickly and with high precision. The most important factor in an SMT placement machine is defining the positions and orientations of the SMD components on the PCB accurately for the machine.

Operation of the SMT placement machine

- The person who designed the machine writes the appropriate “pick and place” for the machine layout.

- The written “pick and place” software is organized in Excel.

- The organized Excel file is divided into 3 programs with capacitors, resistors, and integrated circuits. This program can also be used as a single program.

- After loading the program onto the machine, the directions of the electronic components are prepared on a blank PCB.

- Once the program is ready, the placement machine is prepared for the first program.

- Solder paste is applied to the PCBs using a solder paste printing machine.

- The electronic components to be used in the program are attached to a mechanical device called a “feeder”.

- The feeders with the attached electronic components are attached to the SMT placement machine.

- The machine places the electronic components on the soldered PCBs.

- Once all components are correctly placed, the board is heated in an SMT reflow oven; this melts the solder paste and bonds the components to the board.

- The PCBs coming out of the oven are prepared to be connected to our sensors.

SEVEN Sensor Solution Assembly Line

SEVEN assembly line card production

SEVEN Sensor Solution has a YAMAHA SMT brand placement machine. All processes described in detail above are carried out at SEVEN Sensor Solution using our placement machine. These processes cover the electronic production of all our sensors. For example: Irradiance Sensors, Thermopile Pyranometers, Compact Weather Stations, Wind Speed and Direction Sensors, Dust Sensors, and Temperature Sensors.

Assembling our electronic boards in-house offers advantages such as speed in serial orders and electronic board repair within the scope of technical support. If you would like to review all our sensors assembled using these electronic board processes, please visit: “https://www.sevensensor.com/products”.

Frequently Asked Questions (FAQ)

1. Where are electronic cards assembled?

Electronic cards can be assembled at any company with an SMT assembly line.

2. What should be considered when performing SMT assembly?

The assembly process must be performed in accordance with ESD (Electro Static Discharge) rules.

3. How should SMD components be stored?

ESD components should be stored in humidity cabinets after purchase.